Sheet Cutting Sheet metal cut out is used for air compressor equipment support frame after bending, laser cutting long round hole and welding hexagon nut. The surface is sprayed with black antiultraviolet powder. The relief cut sheet metal is useful in bending metal plate. As a p

Shanghai ETCN Electromechanical Equipment Co., Ltd. [2023-07-21 15:29:39 ]

Part Former Cold Forging As a professional cold forging manufacturer, ETCN provides our clients with precision cold forging die with different types of cold forging die material, such as cold forging brass, aluminium cold forging, cold forging stainless steel and etc. The precisi

Shanghai ETCN Electromechanical Equipment Co., Ltd. [2023-07-21 15:28:50 ]

CNC Turning The parts processed by precision cnc milling turning have the characteristics of good stability and high precision. The added powerhead can complete the machining of parts synchronously by cnc machining milling turning, which is suitable for mass production. The cnc t

Shanghai ETCN Electromechanical Equipment Co., Ltd. [2023-07-21 15:27:53 ]

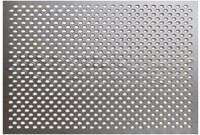

CNC Punching The products processed by CNC punching machines have the characteristics of high stability and high precision, which are suitable for processing large quantities of box products. Advantage of CNC Punching ‚óŹ High processing precision and stable processing quality; ‚

Shanghai ETCN Electromechanical Equipment Co., Ltd. [2023-07-21 15:26:38 ]

Ductile iron is a type of graphite-rich casting iron, but it has not a long history that it was discovered in 1943. Ductile iron actually is not a single material. It\'s a group of materials that can be produced with a wide range of properties through control of their microstruct

Shanxi Rayforce Manufacture Co., Ltd. [2023-06-28 10:10:24 ]

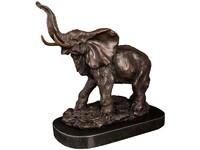

Sculpture Moulding and Casting Rayforce\'s metal casting art can be applied to Home accents, casting crafts, home sculpture, umbrella base, table and chair, patio bench, etc. More Application Marine Agriculture & Vehicle Fluid Control & Hydraulic Pumps & Valves If you want to kno

Shanxi Rayforce Manufacture Co., Ltd. [2023-06-28 10:09:09 ]

Metal Casting Applications Marine Our metal casting china can be applied to anchor, stern frames, anchor winch part, container corner castings, propeller boss... ... Nuclear & Power Plant Rayforce\'s metal casting can be applied to heat exchange machines, boiler, economizer parts

Shanxi Rayforce Manufacture Co., Ltd. [2023-06-28 10:08:45 ]

Die Casting in Automotive Industry Rayforce\'s metal casting truck can be applied to plough, tractor part, soil cultivation, planting, harvesting, hay making, animal feeding machine, etc. More Application Mining & Earthmoving Compressors & Gears Nuclear & Power Plant Fluid Contro

Shanxi Rayforce Manufacture Co., Ltd. [2023-06-28 10:06:54 ]

Shot blasting machine is an effective method to remove the surface contaminant, clean and roughen a smooth surface before applying a primer or coating. Shot blasting equipment is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry

ZIBO RIKEN MT COATED ABRASIVES CO., LTD. [2023-04-28 16:09:11 ]

Direct investment casting, also called the lost-wax casting process, is actually an ancient metal investment casting technology with a history of over 6,000 years. Investment casting mold generally refers to the mold made with meltable materials (such as wax, plastic, etc.) in ve

Shanxi Rayforce Manufacture Co., Ltd. [2023-04-07 13:39:56 ]

Sand casting china is the most commonly applied method for casting the metal part. It suits most of the raw materials, ferroalloy, and non-ferroalloy both can be used to do the sand casting. Types of sand casting is able to produce the part varying from several gram weight to doz

Shanxi Rayforce Manufacture Co., Ltd. [2023-04-07 13:38:36 ]

Casting process usually refers to the metal casting process, is one of heating processing technologies handled by humans can be found recorded as early as 6,000 years ago. This technology has been attained the prime in China during 1,700 ~ 1,000 B C, producing the bronze ware mai

Shanxi Rayforce Manufacture Co., Ltd. [2023-04-07 13:32:51 ]

Environmentally friendly rapid prototyping, higher quality, and lower cost. Printing on demanding, create any your flexible design. 3D printing is one-time printing that reduces the production time and cost. We provide reliable and lower-cost 3D printing solutions for the automot

Xin Pin Prototype Manufacturing Co.,LTD [2023-03-22 10:08:20 ]

Casting is one of the basic processes of modern equipment manufacturing. The casting process can be divided into three basic steps, namely casting metal preparation, mold preparation, and casting processing. Casting metal refers to the metal material used for casting castings in

Shanghai ETCN Electromechanical Equipment Co., Ltd. [2023-02-20 17:50:41 ]

ETCN offers a quality CNC me metal folding/bending press after laser cutting which is used for the base of the compressor motor. Different types of sheet metal bending are available to our clients and meet their satisfaction, like bending stainless steel plate, bending galvanized

Shanghai ETCN Electromechanical Equipment Co., Ltd. [2023-02-20 17:49:23 ]

The silica sol also shares the name of water glass in general. It is used in the metal casting process as mold adhesive which is mixed with sand and several other materials. The silica sol is applied to both sand casting and silica sol investment casting technics. Silica sol inve

Shanxi Rayforce Manufacture Co., Ltd. [2023-02-13 11:28:26 ]

Zinc Alloy Die Casting Zinc die casting is a metal casting process characterized by pressuring molten metal into the mold cavity. The mold cavity is created using two hardened tool steel molds that are machined to the net shape or near net shape of the zinc die casting parts. Zin

Shenzhen Changhong Precision Technology Co., Ltd. [2023-02-08 14:20:33 ]

3D Printing Parts Environmentally friendly rapid prototyping, higher quality, and lower cost. Printing on demanding, create any your flexible design. 3D printing is one-time printing that reduces the production time and cost. We provide reliable and lower-cost 3D printing solutio

Xin Pin Prototype Manufacturing Co.,LTD [2022-12-26 13:54:29 ]

The vacuum dies casting, as this name indicates, is a casting method in which the major processes including melting, pouring, solidifying are performed inside the vacuum chamber. The vacuum is able to minimize the gas content of the product and prevent further oxidation from happ

Shanxi Rayforce Manufacture Co., Ltd. [2022-12-26 09:59:10 ]

The squeeze die casting, also called extrusion casting or liquid die forging, is a kind of newly developed metal forming technic that combines the casting process and dies forging method. The basic principle of squeezing die casting is to fill the liquid metal into the pre-lubric

Shanxi Rayforce Manufacture Co., Ltd. [2022-12-26 09:57:31 ]