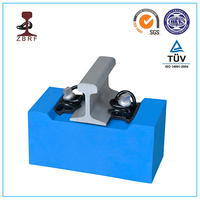

Elastic Rail Clip/ SKL14 Rail clip

Product Quick Detail

- Minimum Order

- 10000

- Place Of Origin

- China (Mainland)

- Materials

- 60Si2Cr,38Si7

- Standard Refers To

- GB/T 1222, DIN 17221

- Hardness

- 42-47HRC

- Fatigue Life

- 5 million cycles

- Packaging

- Woven Bag, Pallet

- Delivery

- 15 Days

Specifications

We produce and supply W14 rail clips according to DIN and GB standard.We source certificated steel manufactuer by CRCC.

We produce the clips with bar size 13mm, 14mm and 15mm.

The testing items including fatigue life, clamping force, hardness, electronic resistance.

This type of fastening are used for UIC54, UIC60, P43, P50, R65, 115RE, 136RE rail tracks, they can also be used crane rail fastening.

If you need further information about this fastening, please contact our sales people.

Zhongbo Railway Fastening Company is a leading Chinese manufacturer of rail fastening and rail joint bar.

Zhongbo, as a specialized rail fastener manufacturer, provides a complete line of products, including rail fastening, anchor, rail joint, rail clip, rail screw, anchor bolt, rail clamp

plate, rail fishplate, and fishplate bolt for connecting rail tracks.

We also make rail fastenings for crane rail and elevator guide rail, along with other related products.We manufacture according to GB/TB (Chinese national standards and railway standards), AREA,

UIC, BS, DIN, ASTM, and AS standards.

Our products are mainly made through hot forging.

The threads of rail screw spikes are made by hot rolling with special threading machines.

We produce metric threads, BS, BSW, TR thread, or round threads.

- Country: China (Mainland)

- Market: USA , Canada, Mexico Brazil, Spain, German, South Africa Nigeria, Russia, Kazakhstan,

- Founded Year: 2008

- Address: No.88 Taowan Center Rd, Shaxi Industry Park, Taicang,

- Contact: dandan li