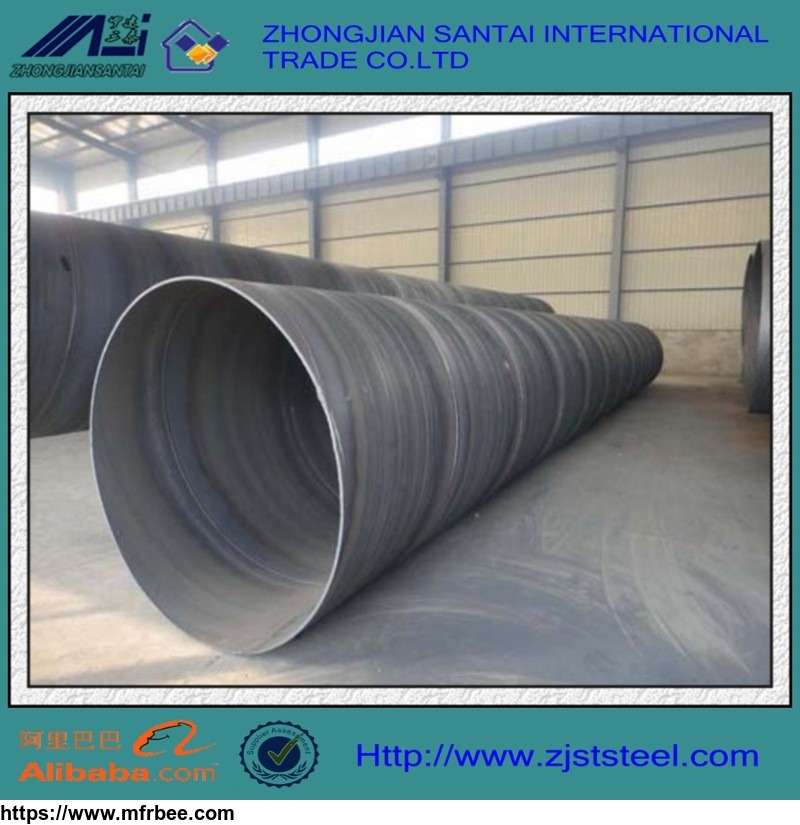

Q235 Large O.D Spiral Welded Steel Pipe

Product Quick Detail

- Technology

- hot rolled Welded steel pipe

- Length

- 5.8 ~ 12.0m or upon customers' requirements

- Wall Thickness

- 0.4-16mm

- Type

- CYLINDER TUBE

- DeliveryTime

- Generally within 30 days after receiving the deposit or L/C at sight.

- Grade:

- SS400,Q235,Q345,Q460, A572Gr.50

- Place Of Origin

- China

- Keyword

- Api 5L Weld Pipe

- Standard

- GB/T3091,GB/T 13793,ASTM A252,ASTM

- Surface

- Prime quality(bared, oiled, color paint, 3LPE) steel pipe

- Package :

- 1. In bundles 2.Waterproof package 3.According to customers' requirements

- Outer Diameter

- 1/8-20 inch

- Application:

- Structure, electric power transmission tower projects, piling, water, oil & gas pipeline engineering, mechanical industry, municipal projects, roads and its auxiliary facilities, etc.

- MOQ

- 10T steel pipe

- Piece

- 24.8

- Minimum Order

- 10

- Packaging

- In bundles

- Delivery

- 15 Days

Specifications

The details of products:

1Definition: welded steel pipe is also called welded pipe which is steel pipe formed by welding the curled steel plates or strip steel, with general

fixed length of 6m.

2Production process: raw material uncoiling â flattening â end cutting and welding â looping â molding â welding â

internal/external removal of welding beads â precorrection â inductive heat treatment â sizing and straightening â eddy current testing â cutting â water pressure inspection â acid

pickling â final inspection (strict control) â packing â delivery

3 Category:

Production methods:

a. Process â electric arc-welded pipes, resistance welded pipe (high frequency, low frequency), gas-welded pipes, furnace butt-welded pipes

b. Welding seam â straight welded pipes, spiral welded pipes

4 Wall Thickness

Thin-wall steel pipes, thick-wall steel pipes

5 End Shape

Circular welded pipes and specially-shaped (square, flat, etc.) welded pipes

6 Length: 6m-12m(capable of being customized and processed according to customer requirements)

7 Surface:Prime quality (bared, oiled, color paint, 3LPE, or other anti-corrosive

treatment)

8 Packing: bundling, nude packing, or packing according to customer requirements

9 Carbon Steel Straight Welded Pipes

Weight (kg) per meter

Note: d (outer diameter); t (wall thickness)

10Features:

Straight welded pipes feature simple production process, high production efficiency, low cost and high development speed.

The intensity of spiral welded pipes is generally higher than that of straight welded pipes; welded pipes with larger pipe diameters can be produced by relatively narrow blanks;

welded pipes with different pipe diameters can be produced blanks with the same width. However, spiral welded pipes have the length increase of 30~100%, as well as lower production speed compared

with straight welded pipes with the same length.

11Application:

structure, electric power transmission tower projects, piling, water, oil & gas pipeline

engineering, mechanical industry, municipal projects, roads and its auxiliary facilities, etc.

CommodityERW / LSAW spiral welded steel pipe from China manufacturer

Outer diameter

ERW LSAW SSAW

1/8-20 inch 12-56 inch 8-126 inch

(10.3-508mm) (323.8-1,420mm) (219.1-3,200mm)

Wall thickness 0.4-16mm 6.0-40mm 6.0-26mm

Length 5.8~12 m or upon customersâ requirements

Standard

GB/T3091,GB/T 13793,ASTM A252,ASTM,A53,ASTM A500,EN 10210, API 5L,DIN 1626/1615,DIN 17120,etc

Grade

SS400,Q235,Q345,Q460, A572Gr.50, A 572Gr.60, S235, S275,S355,Grade A/B, X42, X52, X60,X70,etc

Surface Prime quality(bared, oiled, color paint, 3LPE, or other anti-corrosive treatment)

DeliveryTime: Generally within 30 days after receiving the deposit or L/C at sight.

Payment Terms

1ãT/T: 30% T/T advance, 70 % balance copy of B/L

2ãL/C: 100% L/C at sight

Portï¼ Tianjin

Application:

Structure, electric power transmission tower projects, piling, water, oil & gas pipeline engineering, mechanical industry, municipal projects, roads and its auxiliary facilities, etc.

| Delivery time: | Generally within 30 days after receiving the deposit or L/C at sight. |

|

Package :

|

1. In bundles

2.Waterproof package 3.According to customers\' requirements |

- Country: China (Mainland)

- Market: Europe, Afica,Asia and so on

- Founded Year: 2011

- Contact: Bonnie Xue