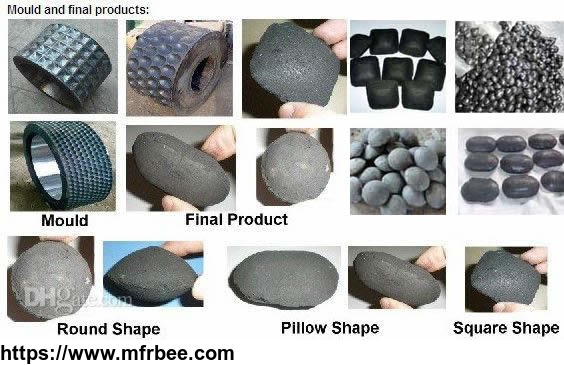

Hydraulic Briquetting Machine/ Sale Hydraulic Briquetting Machine

Specifications

The work of hydraulic briquette machine do not need water. Materials to be processed are all kinds of iron powders, mineral powders, scale, steel slag and refractory material, etc. During the working process of hydraulic briquette machine, we control the balling speed by the ways shown in the following.

.jpg)

Ball bulge grows after being collided. Since water in ball bulge is absorbed by bentonite, it is not easy to be extruded out. Therefore, speed for water to move from inner to surface decreases. If ball surface is not fully wet, balling speed will decrease. What’s the influence of bentonite on balling speed?

As study results show that, along with the increase of bentonite, balling speed decreases. This situation is more obvious if materials to be processed are fine iron ore. Reasons to this phenomenon are the features of bentonite like strong water absorption and water holding.

What’s the influence of water content in raw material for balling speed of hydraulic briquetting machine? If the water content exceeds the limited value, elasticity of raw material will increase. At this time, if we use hydraulic briquette machine to process them, we will get the ball briquettes with poor strength and uneven particle size.

Every kind of raw material has a most suitable water content. Under the limit, balling speed of hydraulic briquetting machine will increase along with the increase of water content. Email us to get more details of hydraulic briquette machine!

Fote Heavy Machinery: http://www.coal-briquettemachine.com/products/hydraulic-briquette-machine.html

Email: vip@sinoftm.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa

- Founded Year: 1994

- Contact: janifer chang