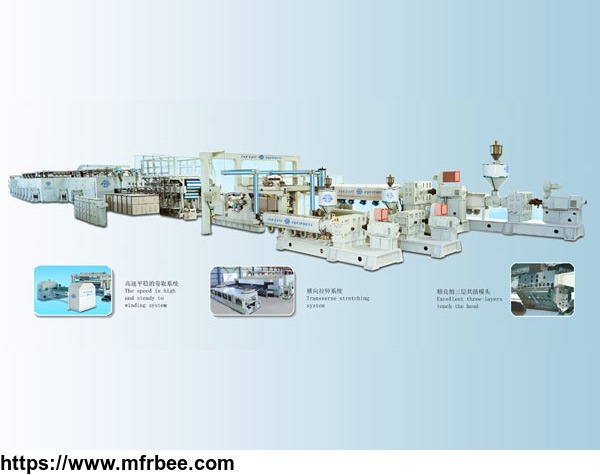

BOPP/BOPET Three-Layer Coextrusion BOPP/BOPET Film Production Line

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- Packaging

- standard packing

- Delivery

- 300days

Specifications

FEBOPP/FEBOPET Three-Layer Coextrusion BOPP/BOPET Film Production Line is developed with our new technologies, on the basis of foreign advanced techniques and domestic technical expertise. The line adopts biaxial orientation technology, through sequential stretching method, to produce heat-sealing or non-heat-sealing type BOPP/BOPET film of single-layer, double-layer or triple-layer (ABC, ABA or AC). The film is characterized by superior characteristics, enhanced tenacity, enhanced mechanical property, cold resisting, heat resisting, good transparence, and good barrier property. Non-heat-sealing film is mainly applicable for printing film, paper/plastic laminated film, and adhesive-tape film. Heat-sealing film is mainly used for packaging of foodstuff, cigarette, tea, textile, etc.

The line is composed of raw-material processing system, extrusion system, cast sheet unit, MDO unit, TDO unit, pulling unit, winding unit, electrical control and temperature control systems. It is characterized by newest design, reasonable structure, and convenient for operation. It adopts advanced modern computer network techniques: the lower computer is SIEMENS PLC-S7 series, and the upper computer is MOTOROLA industrial computer. Human-machine communication is convenient for technological parameters adjustment. With perfect data analysis functions, technology flow is shown in tendency diagrams, so as to judge and solve troubles without delay, and improve the products' quality. The key parts of the line are equipped with international advanced devices. It is up to international advanced level in quality and technology, and meets the demands of production and products' quality. p>

BOPP FILM MACHNE

| Model / Item | Uit | 4200 | 5200 | 6200 |

| Max. Stretching Width | mm | 4200 | 5200 | 6200 |

| Film Thickness | um | 15-50 | 15-50 | 15-50 |

| Film Thickness Tolerance | % | ±3 | ±3 | ±3 |

| Max. Production Capacity per year | t/y | 1000 | 13000 | 15000 |

| Working Speed | m/min | 50-350 | 50-350 | 50-350 |

| Max. Extruding Capacity of Main Extruder | kg/h | 1600 | 2000 | 2200 |

| Extruding Capacity of Assistant Extruder | kg/h | 150-250 | 200-300 | 250-350 |

| MDO Stretching Ratio | 1:1-1:7 | 1:1-1:7 | 1:1-1:7 | |

| TDO Stretching Ratio | 1:7-1:10 | 1:7-1:10 | 1:1-1:10 | |

| Max. Winding Diameter | mm | Φ950 | Φ950 | Φ950 |

| Total Powder | kw | 1600 | 1900 | 2200 |

| Total Weight | t | 350 | 400 | 450 |

| Size (L×W×H) | m | 115×8.5×4 | 115×9.5×4 | 115×10.5×4 |

BOPET FILM MACHINE

| Model / Item | Unit | 4200 | 5200 | 6200 |

| Max. Stretching Width | mm | 4200 | 5200 | 6200 |

| Film Thickness | um | 12-50 | 12-50 | 12-50 |

| Film Thickness Tolerance | % | ±3 | ±3 | ±3 |

| Max. Production Capacity per year | t/y | 15000 | 18000 | 22000 |

| Working Speed | m/min | 50-350 | 50-250 | 50-350 |

| Max. Extruding Capacity of Main Extruder | kg/h | 2200 | 2700 | 3200 |

| Extruding Capacity of Assistant Extruder | kg/h | 250-400 | 300-450 | 350-500 |

| MDO Stretching Ratio | 1:1-1:3.5 | 1:1-1:3.5 | 1:1-1:3.5 | |

| TDO Stretching Ratio | 1:3.5-1:4.5 | 1:3.5-1:4.5 | 1:3.5-1:4.5 | |

| Max. Winding Diameter | mm | Φ950 | Φ950 | Φ950 |

| Total Powder | kw | 4500 | 5000 | 5500 |

| Total Weight | t | 400 | 450 | 500 |

| Size (L×W×H) | m | 115×9.6×4.5 | 115×10.6×4.5 | 115×11.6×4.5 |

- Country: China (Mainland)

- Market: Asia,Americas,Europe,Middle East,Africa

- Founded Year: 1985

- Address: Far East Industrial Garden, Xinxi Town, Shantou, 515022, China

- Contact: Jason Chen