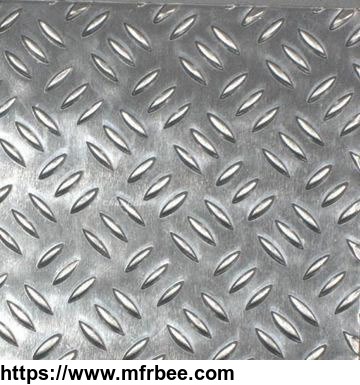

Checkered steel plate

Specifications

Checkered steel plate can be divided into three types: checkered carbon steel, checkered

galvanized steel and checkered stainless steel plates. Can be supplied in coils or sheets.

Galvanized Steel Checker Plate:

Galvanized checker plate refers normally to hot dipped galvanized steel plate with zinc coating

layer. The galvanizing on the steel sheet surface will help avoid rusting when the checkered

steel plate is exposed to moisture environment. The zinc coating amount will meet Chinese or

international standard requirements. With a certain degree of slip resistance, good corrosion

resistance, beautiful appearance and economic cost, galvanized steel checker plate is widely used

in elevator decorative plate, shops decoration, engineering, exterior design of the building, etc

Checkered Carbon Steel Plate:

This is the base metals for galvanized checker plate, seldom supplied without further coating. It

costs less compared with other checkered steel, yet easily get rusty.

Stainless Steel Checkered Plate Coils or Cut to Size: 300 Series as most popular materials.

General Technical Introduction:

Major stainless steel sheet material: SS 300 series, 200 series and 400 series. 200 series:

201,202.

300 series: 301,304,304H,304N,304L,304LN,309S, 310S,316,316Ti,316L,316N,316LN,317,

317L,321,321H,347,347H.

400 series: 405,409,403, 430,410,420, 440c.

Thin gauge 2mm to 6mm; thick gauge 6.00mm to 12.70mm.

Stainless steel has good mechanical properties with including excellent corrosion resistance,

heat resistance.

Standard followed: ASTM,AISI,GB,JIS,SUS,EN,DIN and etc.

Hot rolled or cold rolled steel.

Application: Stainless steel Checkered plate is widely used in high corrosion resistance

conditions such as chemical, hospital and food related conditions, details as below:

1: As stepping or decking parts for large chemical industry equipment or industrial tanks;

2: Components or fittings of medical instruments, tableware, kitchen utensil, kitchen ware;

3: For making of milk or food processing facilities;

4: Hospital equipment;

5:Architectural purposes, interior and exterior decoration for building, escalators.

Stainless steel metal raw materials have a stable chemical composition (details see table below)

and mechanical properties. It will not react with other elements easily. Hence, the finished ss

checkered plate is suitable to be used in a tough environment, like chemical plant.

The features of corrosion resistance and weather resistance and beautiful surface treatment make

it also suitable for architectural outdoor uses like façade and wall panels, ceiling panels, etc.

SS checkered metal panels have excellent abrasion resistance, less wear at the sharp, non-slip

effect is large and rich in durability addition. Weight can be reduced compared to ordinary steel

checkered plate because of the high intensity of use per unit area. By using stainless steel

material, the customers need not worry about getting rust – a problem mostly occurred with

common steel checkered sheets.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Asia

- Founded Year: 2006

- Address: 51 of Mingzhu Park Building, Dezhou Development, Dezhou, China

- Contact: yang guang