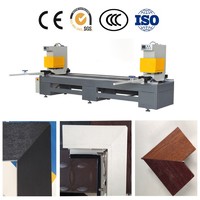

butyl extruder machine insulating glass machine

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- FOB Price

- USD $3,000.00 / Piece

- Packaging

- plywood case

- Delivery

- 15 Days

Specifications

JT02 Butyl extruder machine

Main Features

1. It is used for butyl sealant coating on two sides of Aluminum spacer frame.

It’s a necessary machine for making insulating glass machine.

2.It is equipped with photoelectric and PLC controlling systems, and high-temperature resistance conveyer belt.

3. The widthbetween two nozzles can be adjusted as per spacer width.

4. The heating time and speed can be adjusted

5. It’s equipped with alarming system. The worker can fill the butyl in time while it is using up.

Technical parameters

| Working voltage | 380V 50Hz |

| Total power | 1.25KW |

| Air pressure | 0.6 ~ 0.8Mpa |

| Coating speed | 0-28m/min |

| Spacer width | 6 ~ 20mm |

| Heating temperature | 120 ~ 140°C |

| Squeeze pressure | 12 ~ 18MPa |

| Machine dimension | 3300x800x1400mm |

| Weight | 700KGS |

We sincerely hope to cooperate with clients from all over the world.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Middle East,Europe,Oceania

- Founded Year: 2005

- Address: No. 186, Huayuan Road, Licheng district

- Contact: Tammy Ma