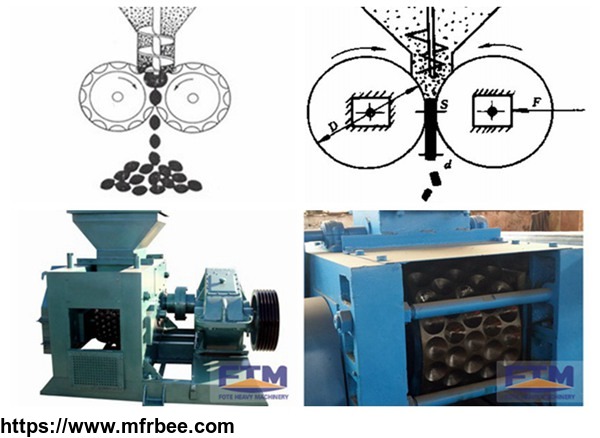

Coal Briquette Press Suppliers/Coal Briquette Machine

Specifications

For manufacturers of coal briquette press machine, how to survive from the serious competition is a question that worthy of consideration. The normal way is to lower the production cost. Along with the increasing demands for coal briquettes, price of coal briquetting plant is elevated all the time. The marketing situation of coal briquette machine becomes more and more unstable. Then, how to lower the production cost in a reasonable way?

When we reduce the selling cost, the selling efficiency must be elevated. The so-called selling cost is the sum of travel cost and channel cost. Controlling the selling cost in a limited scope can improve the selling efficiency. Secondly, we can improve the quality of coal briquette press to reduce the cost and time for maintenance. By improving the production technique and operational standard of coal briquette machine

Innovations on the design details of coal briquetting plant can not only save the production cost, but also can bring up the technological development. As a professional manufacturer featuring in rich production experience and strong ability for research and development, Fote briquetting machine manufacturer

official website: http://www.coal-briquettemachine.com/products/coal-briquette-machine.html

email: vip@sinoftm.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa

- Founded Year: 1994

- Contact: janifer chang