Multiple composite pipe

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- Packaging

- in wooden boxes

- Delivery

- 15 Days

Specifications

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Americas,Asia,Europe,European Union

- Founded Year:20000

- Address:No. 273, Siping Road, Shanghai

- Contact:sum xu

Other products from Sunny Steel Enterprise Ltd.

Relate products of Multiple composite pipe

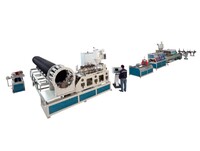

As a leading pipe extrusion machine line supplier, Jwell provides quality composite pipe extrusion production lines for RTP. RTP (Reinforced Thermoplastic Pipe) is a new type of pipe that combines the unique advantages of thermoplastic(PE80, PE100, PA, PER, PVDF, etc), such as ...

Brief Introduction of Steel-plastic Composite Pipe 1. Executive standard: GB / t28897-2012 2. Application: transportation of drinking water, hot and cold water, fire water, drainage, air conditioning water, medium and low compressed gas, compressed air and other media 3. ...

FREE-VALVE’sCeramic Lined CompositePipe and Ceramic Elbow include elbow, short section ,Tee joint ,reducer etc ,which are widely used in the powder of pneumatic conveying and pumping conveying . Due to the large abrasives , high hardness ,high speed ,large flow rate of medium ...