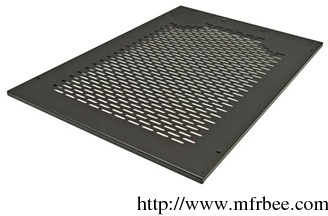

Aluminum Perforated Panel - perforated aluminum sheets

Specifications

Aluminum Perforated Panel

Perforated aluminum panel has a strong resistance to corrosion due to an oxide skin formed in reaction with the atmosphere. It is a relatively light metal compared to metals such as steel, nickel, brass, and copper and is rather malleable. It can have a wide variety of surface finishes and is highly reflective to heat and light. For most applications, perforated aluminum sheets need no protective coating but are often anodized to improve color and strength.

Perforated aluminum panel has a strong resistance to corrosion due to an oxide skin formed in reaction with the atmosphere. It is a relatively light metal compared to metals such as steel, nickel, brass, and copper and is rather malleable. It can have a wide variety of surface finishes and is highly reflective to heat and light. For most applications, perforated aluminum sheets need no protective coating but are often anodized to improve color and strength.

Aluminum perforated panel is extremely useful at low-temperatures. At subzero temperatures its strength increases while retaining ductility. At temperatures over 400F aluminum alloy sheets tend to lose some of their strength.

- Country: Afghanistan

- Market: Africa,Americas,Asia,Emerging Markets,European Union,G20

- Address: 22 Mingqin street, Anping, Hebei, China.

- Contact: hui zhang