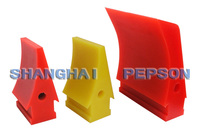

Open Cast Polyurethane Urethane Thermoset Rubber Products

Product Quick Detail

- FOB Price

- USD $5.00 / Piece

- Minimum Order

- 200

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Using the very latest polyurethane casting technology, we can produce high-quality cast parts. By varying the raw materials, formulations and methods of manufacture, we can influence the properties

to meet specific requirements.

We are able to manufacture complex geometries, also with larger components, and all with the outstanding properties of a polyurethane.

Casting technology allows us to use simple moulds to produce small and large batches inexpensively. They can also be permanently bonded to other materials (steel, aluminium, cast iron, etc.).

Our highly trained applications engineers can provide you with optimum, individual advice on your product.

We can cast parts with weights of up to 500 kg. All materials can be adapted to suit their respective applications. We can influence the hydrolosis resistance, microbe resistance, colour and

hardness. The materials can also be made electrically conductive. For careful handling during assembly operations in the automotive industry, we have the option of providing a material that leaves

absolutely no residue on surfaces which might impair the paint finish.

We can offer all grades, from 5° Shore A to 95° Shore A, even up to 80° Shore D. We can process hot- and cold-casting polyurethanes. And our 80° Shore D material can even be used to replace steel

parts.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20

- Founded Year: 2004

- Contact: ban xue