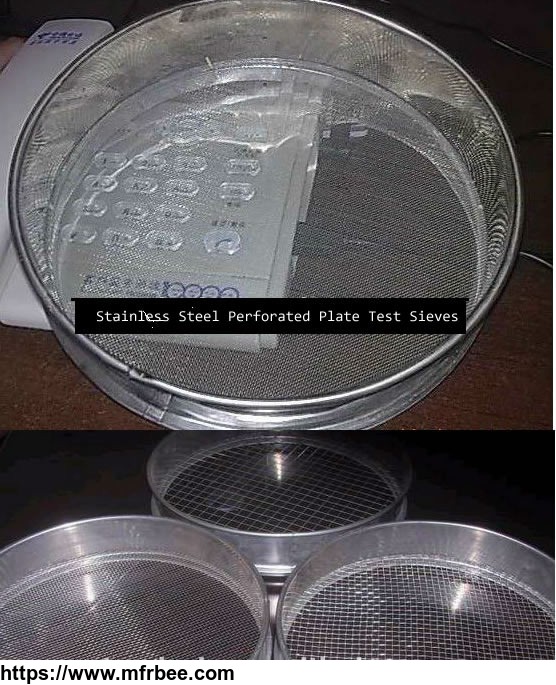

Stainless Steel Perforated Plate Test

Specifications

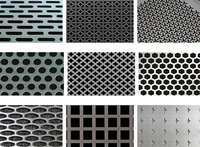

Major Types of Perforated Sieves include Grain Sieve, Mid-Point / Half Height Sifting Sieve and Extra Depth Sieves. Applied for Various Grading and Sifting Uses. Mainly made of Stainless

Steel Perforated Sheet with Round Hole.

Perforated stainless steel plate sieves are made of punched metals with slotted round holes. The metal sieves are available in diameter sizes of 200, 300, 315, 350, 400 and 450 mm. The particle

sizes of the square hole perforate sieves range from 125 mm to 4 mm. The sizing range for the round hole perforated sieves are 125 mm to 1 mm. SS perforated sieves are designed with for certain

purpose like grain sieves, mid-point grading test sieves and extra depth perforated metal sieves. Popular sieves are 80ea Round Hole Perforated Plate Sieves, Processed from Stainless Steel 300

series, 23 Gauge, with 1/16 perforations, OD of the Sieve is 13&1/4", Height of Sieve is 2". Special apertures can be customized.

Stainless Steel Perforated Grain Grading Sieves

This grain sieves are used by agriculture department and grain organizations worldwide for testing grains and cereals grades. Commonly the stainless steel slotted plate is framed with 200 mm

diameter brass or stainless steel frames to form a sieve device.

The aperture sizes as specified in ISO 5223.

Hole patterns for grain sieves: round or square depending on the grain sizes and shapes it will measure. In addition, perforated sieves for special purposes such as shaped holes, wet washing, very

small openings and for use with specialize equipment are available.

Extra Depth Sieves Made with Perforated Metal Plate as Screening Materials, Ensuring a Long Time Sifting Uses:

Perforated stainless steel sieves are made in the shape of extra depth extensively used by the construction and cement industries. The diameter size is commonly 450 mm and the sieve depth is 300

mm. Made from stainless steel perforated sieving media, the sieve is strong and rigid and work for a long time without breaking.

Perforated Mid-Point Standard Test Sieves for Sand Sifting, As Master Stack

Stainless steel perforated sieve has a range of shapes and styles and is used widely in many ways. A mid-point test sieve has had the mesh inspected. The sieve is then selected as a mid-point if

the results give tolerances that are in the middle of the ASTM Standard. For example, the ASTM permissible variations for the mesh of a No. 40 sieve (425µ) are:

1:Average Opening ±19µ.

2:Opening Dimension of 396µ not exceeded by more than 5% of the openings.

3:maximum individual opening 502µ.

The mid-point would have a variation in Average Opening of ±9.5µ, opening dimension of 396µ not exceeded by more than 2.5% of the openings and a maximum individual opening of 463.5µ. The effect of

this tightened tolerance is an improvement in variation of approximately 30%. These results are traceable to a NIST standard.

Mid-Point Perforated Sieves are used as master stack:

When a process requires a high level of repeatability, mid-points can be used on all sieve tests. However, the predominant application for the mid-point sieves is as master stack. A master stack is

used to check and recalibrate sieves used in everyday testing. It can be also used for the screening of sand.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia

- Founded Year: 1998

- Address: Silver Time Road, Dezhou, Shandong, China

- Contact: Sunny Green