Covered Fiberglass Grating

Specifications

Covered Fiberglass Grating - Solid Cover for Heavy Load

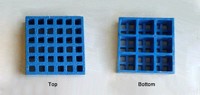

Covered fiberglass grating is designed for loading and storage areas with high foot and cart traffic. The fiberglass covered grating panel has one solid fiberglass plate attached to the top

surface, which offers strong, level surface and higher stiffness values than that of open mesh gratings. Covered gratings come in two categories: covered molded fiberglass grating and covered

pultruded fiberglass grating.

Covered molded fiberglass grating

It is a one-piece molded grating with fiberglass gritted plate cover secondarily fastened to a molded grating panel. It offers solid flooring to prevent contamination of work surfaces below, to

control subsurface odors or to prevent tripping hazards for narrow heels.

Covered pultruded fiberglass grating

Covered pultruded fiberglass grating has a top surface available in smooth or gritted top. It is ideal for turning wheel traffic areas or conditions when necessary to eliminate passage of air or

debris.

This is one fiberglass covered grating in yellow, the covered plate has decorative pattern.

CFG-01: The covered grating is stiffer than common open mesh gratings, and the decorative pattern adds beauty to the grating.It is one piece of covered grating, the covered plate has decorative

pattern on the surface.

CFG-02: Covered FRP grating is typically used for sewage treatment plant.

It is one piece of covered fiberglass grating with gritted surface.

CFG-03: Covered fiberglass grating with gritted surface is anti-slip and the colour of grating has wide selection.It is one covered pultruded grating with gritted top surface.

CFG-04: Covered pultruded grating with gritted top surface.

Three pieces of covered fiberglass gratings are placed, two are gray and one is red.

CFG-05: We offer various colours of covered gratings, and the decorative pattern of the top surface is made as per need.It shows that one piece of translucent green covered FRP grating with

translucent cover plate.

CFG-06: Custom fabricated product - translucent green covered FRP grating.

Feature

Corrosion and chemical resistance.

Slip resistance.

Impact resistance.

Fire retardant.

Increased product stiffness.

The cover offers safe footing.

Light weight.

Low maintenance.

Long service life.

Specification

Colours: gray, green, yellow, charcoal. (Other colours are available).

Patterns: smooth covered, gritted covered and decorative covered.

Standard thickness of covered plate: 3 mm, 6 mm. (Other thickness is available as per customers' special request).

Standard panel size (mm): 1220 × 3660, 1000 × 2000. Panels can also be cut to size.

Application

Waste water treatment plants.

Food industry.

Water cycle.

Food processing facilities.

Marine environment loading docks.

Manufacturing industry.

Trench covers.

Walkways over tank tops and vats.

It shows that in a waste water treatment plant, there installed with covered fiberglass gratings.

CFG-07: One typical application of the covered fiberglass grating is to provide a walking surface and control subsurface odors in waste water treatment plants.There are several pieces of green

covered FRP gratings that placed above the ground.

CFG-08: Green covered FRP grating with checkered plate applied in industrial areas.

It shows that in a wastewater treatment plant, the FRP covered grating works as walkway.

CFG-09: Covered FRP grating used in wastewater treatment plant to control subsurface odors as well as offering walkways.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Americas

- Founded Year: 1996

- Address: Science and Technology Park in Zaoqiang County, Hengshui City, Hebei Province, China

- Contact: fei feng