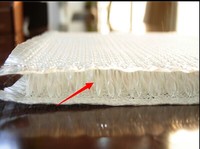

Fiberglass chopped strand mat

Product Quick Detail

- FOB Price

- USD $1.20 / Piece

- Minimum Order

- 1000

- Place Of Origin

- JIANGXI

- Areal Weight

- 300g/m2,450g/m2,600g/m2

- Application

- Pipe,auto parts,boat

- Key Words

- E-glass chopped strand mat

- Packaging

- carton

- Delivery

- 15 Days

Specifications

Technial Specification:

| Spec. (g/sqm) | Width (mm) |

Area Weight (g/m2) |

Moisture Content | Combustible Content (%) | |

| Powder (EP) | Emulsion (EE) | ||||

| CSM100g/m2 | (50~3120)±5 | 100±10% | ≤0.20% | 8.0-9.8 | 7.5-8.0 |

| CSM120g/m2 | (50~3120)±5 | 120±10% | ≤0.20% | 8.0-9.8 | 7.5-8.0 |

| CSM200g/m2 | (50~3120)±5 | 200±10% | ≤0.20% | 3.6-4.5 | 4.5-5.5 |

| CSM225g/m2 | (50~3120)±5 | 225±10% | ≤0.20% | 3.0-5.0 | 3.0-5.0 |

| CSM300g/m2 | (50~3120)±5 | 300±10% | ≤0.20% | 3.0-5.0 | 3.0-5.0 |

| CSM375g/m2 | (50~3120)±5 | 375±10% | ≤0.20% | 3.0-5.0 | 3.0-5.0 |

| CSM450g/m2 | (50~3120)±5 | 450±10% | ≤0.20% | 3.0-5.0 | 3.0-5.0 |

| CSM600g/m2 | (50~3120)±5 | 600±10% | ≤0.20% | 3.0-5.0 | 3.0-5.0 |

| CSM900g/m2 | (50~3120)±5 | 900±10% | ≤0.20% | 3.0-5.0 |

Compatible Resins and Application:

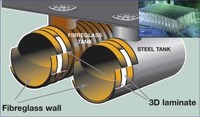

Powder Chopped Strand Mats are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins. Powder Chopped Strand Mats are available with width range of 50mm~3120mm. The products are available with different wet-out and break up speeds, depending on the requirements of customers. The products are most widely used in hand lay-up and can also be used in filament winding, compression molding and continuous laminating processes. The typical end-use applications include various panels, boats, bathroom equipment, automotive parts and cooling towers.

- Country: China (Mainland)

- Founded Year: 2004

- Address: Jiangxi,jiujiang city

- Contact: Michelle Xiang