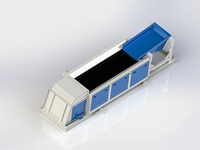

Nut Shell&Kernel Separating Machine

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

- Country: China (Mainland)

- Business Type: AZEUS Machinery

- Market:

- Founded Year:2003

- Address:

- Contact:nicole yang

Other products from Zhengzhou Amisy Trading Co.,Ltd

Relate products of Nut Shell&Kernel Separating Machine

Features 1. Widely used in the field ofblood bank, pharmaceutical factory and laboratory. 2. Brushless frequency motor, in great torque, free maintenance, no powder pollution, quick in speed up and down. 3.Digital display which indicates theprogram, speed, time,RCF, ...

Finish: ZINC PLATED, Black Oxide, galvanized, passivated, Nickel Plated, ZINC PLATED, Black Oxide, galvanized, passivated,Nickel Plated Measurement system: Metric, Imperial (Inch), Metric, Imperial (Inch) Application: Heavy Industry, Mining, Water Treatment, Healthcare, Retail ...

Magnetic eddy current separator machine is also known as non-ferrous separators, which uses the induction principle (eddy current) of a high-frequency magnetic field to separate non-ferrous metals. High-capacity permanent magnet drum traveling at a high speed inside an eddy ...