Stair Tread Steel Grating for Industrial Application

Product Quick Detail

- Place Of Origin

- china

- Minimum Order

- 1

- FOB Price

- USD $500.00 / Piece

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Stair tread steel grating is one of the most widely used application of steel bar grating. It can be installed in the factories or in the parks for the permanent or temporary using.

Stair tread can be made of low carbon steel, aluminum steel and stainless steel gratings. The low carbon steel grating can be galvanized and painted for better corrosion resistance.

Types of stair tread steel grating

- According to the different fabrications of stair treads grating, it can be divided into welded stair treads, press-locked stair treads, swage-locked stair treads and riveted stair treads.

- Among the four types, the welded grating stair tread is the most widely used type. It has firm structure and simple technology.

- The press-locked and swage-locked stair tread can supply better lateral stiffness than other types of gratings.

- And the riveted stair treads features higher load carrying capacity for longer service life.

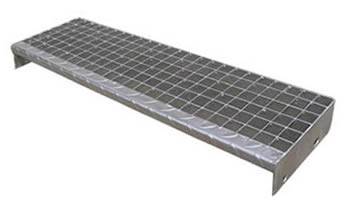

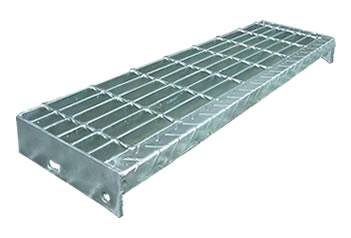

Welded steel grating stair tread.

Swage-locked steel grating stair tread.

Riveted steel grating stair tread.

Press-locked steel grating stair tread. - According to the fixing type, it can be divided into bolts connections and welded connections.

- The bolts connection stair treads grating allows for the temporary using and easy installation and uninstallation.

- The welded connection stair treads features durable and firm structures, it can be used in the permanent applications.

Welded connection stair tread.

Bolts connection stair tread. - According to the front nosing, it can be divided into without nosing, checker plate nosing, vertical stripped plate nosing and round hole plate nosing.

- Without nosing stair treads grating is available for common applications.

- Different nosing type can improve the slip resistance performance of grating, it is suitable for wet or slip applications.

Stair tread without nosing.

Checker plate nosing stair tread.

Vertical stripped plate nosing stair tread.

Round hole plate nosing stair tread. - According to the stair tread grating surface, it can be divided into smooth or plain surface and serrated surface.

- The smooth surface stair treads have even surface which is artistic and is suitable for common applications.

- The serrated surface stair treads has better anti-slip performance, which can be used for special applications.

Serrated surface stair tread.

Smooth surface stair tread.

Specifications of stair tread steel grating

- Material: low carbon steel, aluminum steel and stainless steel.

- Surface treatment: galvanized, painted, mill finished and other surface treatment.

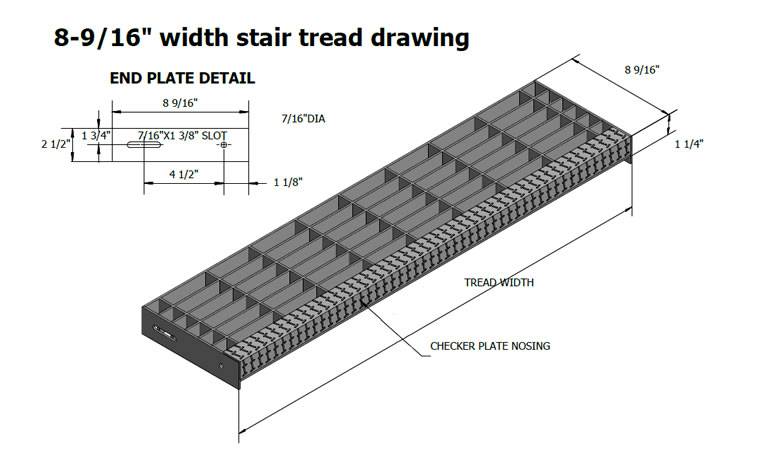

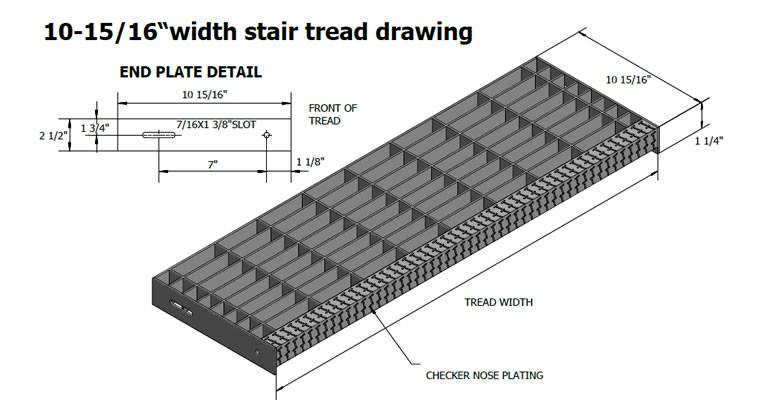

- Tread width: 8-9/16" and 10-15/16", special sizes can be customized.

- Tread length: 30", 36", 48" and other sizes are available.

- Tread height: 1-1/4".

- Bolt hole center distance: 4-1/2" and 7".

8-9/16" width stair tread drawing.

10-15/16" width stair tread drawing.

Features of stair tread steel grating

- Easy to install and uninstall. It doesn't need any complicated skills. Welding and bolts connections types for choice.

- Good ventilation of light, air and water. Large holes of stair treads make it easy for light and air ventilation.

- Slip resistance. Serrated surface and nosing added can improve the slip resistance performance.

- High strength and high load carrying capacity. Riveted steel grating stair treads supply high load carrying capacity.

- Corrosion resistance. Aluminum steel grating and galvanized steel grating can ensure the outstanding corrosion resistance of stair treads.

- Alkali and acid resistance. Stainless steel stair treads has excellent chemical stability for long service life.

- Low maintenance cost. It is easy to clean the dust and dirt and cost less.

- Good drainage. The large holes of stair treads make it easy to drain water and keep the stair treads dry.

Applications of stair tread steel grating

- The bolts and welding connection types makes stair tread steel grating be used in permanent or temporary applications.

- Serrated surface improve the anti-slip performance, so it is ideal grating to be used in the wet, slipping areas.

- Good drainage performance let the stair treads be available for outdoor stairs.

- The stair treads can be used in the corrosive and harsh environments due to the good chemical stability characteristic of stair treads.

Serrated surface stair treads can be used in the wet and slippy areas.

Bolts connection stair treads can be used in the temporary applications.

Stair tread is available for commercial and industrial applications.

Good drainage performance make the stair treads can be used as outdoor stairs.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Asia

- Founded Year: 1992

- Address: East industrial Zone, Anping, Hebei, China.

- Contact: zhang yu