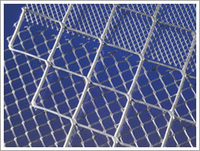

Stainless Steel Wedge Wire Screen

Specifications

Wedge wire screen is a kind of effecitve sand control filter screen manufactured by wrapping a profile wire cylindrical around longitudinal placed support rods. All wires and rods are

resistance welded at each point of contact. The numerous combinations of profile wires and support rods enables a flexible design with a wide range of apertures by changing the wires and rods

structure. Hence we can supply wedge wire screen according your technical or cosmetic specification. We supply wedge wire in the forms of pipe screen or sieve bends.

The v-wire or wedge wire tapered opening becomes progressively wider toward the interior of the well screen. This produces a non plugging opening ( unlike mesh construction)that has only two

contact points to retain sand particles, thus increasing efficiency and lowering entrance velocity.

Our stainless steel wedge wire well screens are manufactured using unique computer controlled machinery in which a continuous length of profile wire of a triangular section is fusion welded into

support rods. This 'V' shaped profile wire is wound around the support rods over the full length of the screen thus creating a continuous slot opening.

Processing and Structure:

Stainless steel wedge wire screens are manufactured using unique computer controlled machinery in which a continuous length of profile wire of a triangular section is fusion welded into support

rods. This 'V' shaped profile wire is wound around the support rods over the full length of the screen thus creating a continuous slot opening.

Advantages:

A continuous slot opening which significantly increases the available open area, thus providing a greater access to the water bearing zone.

Uses: Stainless steel wedge wire /profile wire/ wire wrapped screen is the most cost effective filter solution used for solid / liquid and solid / gas separation, sizing, dewatering and media

retention in Oil & Gas wells, Water Wells, monitoring & soil sanitation, the ( petro )chemical industry, food and process industry and architecture.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia

- Address: Rm.409,Zhongyu,No.1618,North Youyi Road ,Dezhou ,Shandong.

- Contact: li dong