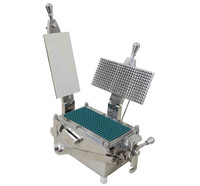

Automatic Tube Filling Machine

Specifications

Kahan International's tube fillers fill products in cylindrical metal / laminate / plastic(seamless) tubes and close it absolutely safely and symmetrically. 4 models, in capacities ranging from 30 to 120 tubes / minute are available to meet today’s tube packaging demands. KI-ARTF40 is the automatic model with an output of 40 tubes per minute. A variety of viscous and semi-viscous products are handled, like ointment, cosmetics, toothpaste, cream/gel, adhesive, chocolate, sealant, mayonnaise and many more. Quick, easy & efficient changeover is the leading attribute of the machines, which helps in responding to the faster-time-to-market age we live in. The optional equipment available with the machines adds to the versatility.

Machines are designed and constructed by qualified engineers with good quality material and components which gives best quality output and least breakdowns.

product link : https://www.kahaninternational.com/dt-87

Features:

- Machine as per cGMP standards.

- Complete Stainless steel Constructed.

- Delta/Omron/Schiender/Allen Bradely make HMI Touchscreen(7 inch size).

- Delta make PLC operated machine.

- All sensors are Omron make.

- All pneumatics are Pneumax/Festo make.

- All swithces are standard L&T make.

- 4 nos SS castor wheel.

- Piston block filling system.

- Drip proof Shut off nozzle.

- Camfield make Indexer for indexing system.

- 1 Hp Hindustan make motor.

- Output: 40-45 tubes per minute

- Filling size : 5 gms to 250 gms

- Leister(Swiss) make Hot air Gun for Laminated/Seamless tubes.

- Optional: Safety Cabinet with Polycarbonate Doors.

- 12 station rotary system.

- Automatic Emergency stop of the machine in case of non ejection of the tube at ejection station.

Working Process:

| Station | Laminated/Plastic Tubes | Aluminium Tubes |

| 1 | Automatic Tube Loading | Automatic Tube Loading |

| 2 | Optional: Automatic Vacuum Tube Cleaning | Optional: Automatic Vacuum Tube Cleaning |

| 3 | Automatic Tube Orientation | Automatic Tube Orientation |

| 4 | Automatic Tube Filling | Automatic Tube Filling |

| 5 | Empty (No process) | Tube Press |

| 6 | Heating(Leister make Hot Air Gun) | First Fold |

| 7 | Automatic Tube Sealing | Second Fold |

| 8 | Empty (No process) | Optional: Third Special M Fold/Double Fold |

| 9 | Automatic Tube Coding and Trimming | Empty (No process) |

| 10 | Automatic Tube Ejection | Automatic tube Coding |

| 11 | Non Ejection of tube Sensing | Automatic Tube Ejection |

| 12 | Empty (No process) | Non Ejection of tube Sensing |

Electrical Specifications:

| Power Input | 440 V ± 5 V Three Phase |

| Conveyor motor capacity | 1 HP, 440 V ± 5 V Three phase, 1440 rpm |

Compressor:

3 Hp Motor, 5-6 kgf/cm2 with 9 cfm flowrate.

Weight (Net):

Approx 500-600 kg

Dimensions (L x W x H):

Approx 7 x 4 x 7 feets

- Country: India

- Business Type: Manufacturer

- Market: Africa,Emerging Markets,Asia,Americas,Middle East

- Founded Year: 2015

- Address: Gala No 6, Ground Floor, Crescent Industrial Estate, Behind Classic Stripes, Chinchpada, Waliv Road, Vasai East - 401202, Mumbai, Maharashtra, India.

- Contact: Purvik Shah