Steel-edge Waterstop

Specifications

Steel-edge waterstop is a modification of traditional rubber waterstop with steel plate rings being inserted into the

middle of vulcanized rubber. High liquid-tightness and high absorption of shear movements make the steel-edge waterstop a recommended choice for expansion, contraction joints and other construction

fields with high pressure and structure variable.

Once the structure sedimentation, concrete shrinkage and creep occur, the rubber parts of steel-edge waterstops will be elongated and thin to adjust to these deformations without affecting the

adhesion between steel plates and the rubber part, between steel plates and the surrounding concrete. In this way, the steel-edge waterstops are able to withstand greater tension and torsion than

traditional waterstops; meanwhile, it effectively prevents concrete loosen, breaking off and the form of leaking cracks.

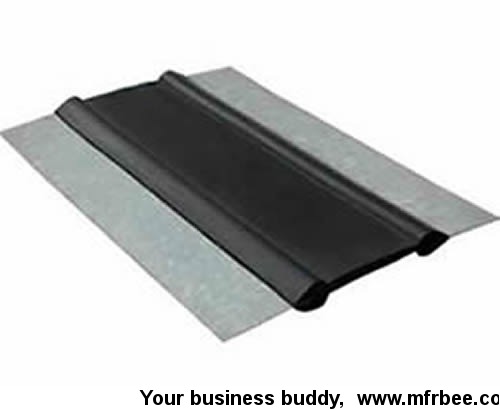

A piece of steel-edge waterstop

Steel-edge waterstop

Feature & benefits:

Quality EPDM rubber with high tensile strength.

Galvanized steel plate for high rust and corrosion resistance.

With punched holes on the steel plate for easy installation.

Adjustable to high movements and deformations.

High adhesion between the steel plates and the rubber.

Excellent fastness between the steel plates and surrounding concrete.

Custom types are welcomed.

Applications:

A diagram of steel-edge waterstop

A diagram of steel-edge waterstop

A diagram of steel-edge waterstop

Water conservancy projects.

Dams, tunnels and channels.

Basements of high-rise building.

Slabs and wall junctions.

Duct piece joint of shield segment tunnel.

Construction, expansion and contraction joints.

Conduit joints and infrastructure deformation joints.

Underground engineering.

- Country: China (Mainland)

- Founded Year: 1983

- Address: Development zone, South Wang zhuang, Pengdu, Hengshui, Hebei, China

- Contact: Last Name Yang