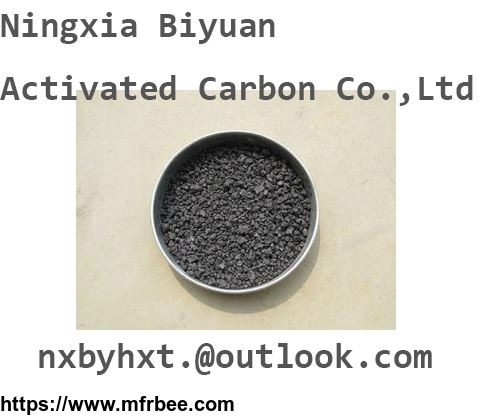

calcined anthracite

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- 25 kg bag/50 kg bag/1 MT jumbo bag for C 99% Calcined Anthracite Coal Carbon Additive for Steelmaking.

- Delivery

- 7 Days

Specifications

Calcined anthracite

The main application of calcining anthracite coal is fertilizer (nitrogen fertilizer, synthetic ammonia), ceramics, manufacturing forging and other industries. The main application of anthracite powder is used in the metallurgical industry for blast furnace blast (blast furnace blast coal mainly includes anthracite, lean coal, lean coal and gas coal).It is used for the filtration and purification of water supply and industrial water supply. According to the form of the filter in the use of the parameters, the pavement thickness of the normal double layer filter is 300-400mm; Normal filter speed 10-14m/h, force filter speed 14-1 8m/h; The thickness of the three-layer filter is 450mm, the normal filter speed is 18-20m/h, and the filter speed is 20 ~ 25m/h. Water flushing, water vapor flushing or surface rinsing is used in the filter backwash.

- Country: China (Mainland)

- Business Type: Export

- Founded Year: 2010

- Contact: anna yan