Pot Bearing

Specifications

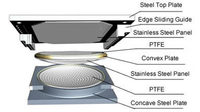

Pot bearing, with elastomeric bearing pad fitted inside of steel plate, is the widest used type for transferring

vertical or horizontal loads from superstructure to the pier as well as allowing rotations on any axis. Meanwhile, it’s capable to accommodate horizontal displacements of superstructure taking

advantages of the reduced friction coefficient between stainless steel panels and a layer of PTFE.

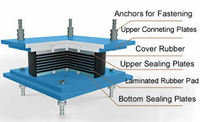

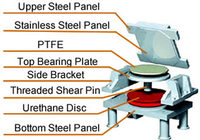

A diagram of a free sliding pot bearing

Components of free sliding pot bearing

Components:

Steel top plates - capable to accommodate longitudinal or transverse sliding movements of the superstructure.

Stainless steel panels & PTFE - reduce the friction resistance as well as horizontal force.

Steel piston & internal brass sealing ring - protect the elastomer pad from extrusion.

Elastomeric pad - behaves like a fluid under high pressure and allows higher working pressure with reduced dimensions.

As your request, external rings can be supplied to make sure that the gap between piston and steel pot is free of moisture and debris.

Features:

With low-profile yet high loading capability over 50,000 KN.

Maximized shearing strength of elastomer pad through the method of encasing it in the steel pot.

Allow for large rotations ranging from 0 to 0.03 rad.

Low friction coefficient between 1% and 3%.

Excellent fatigue, impact and aging resistance of the layer of PTFE.

All the metallic parts are protected against corrosion by galvanization and epoxy painting according to EN 1337-9 (other protective coatings are available as your requirements).

Easy and quick to install.

Easy to maintain and replace the worn out and broken part.

Complying with BS EN-1337, KS4424, AASHO, ISO or other custom standards.

- Country: China (Mainland)

- Founded Year: 1983

- Address: Development zone, South Wang zhuang, Pengdu, Hengshui, Hebei, China

- Contact: Yang Hui