Super Abrasives CBN Micron Powder

Specifications

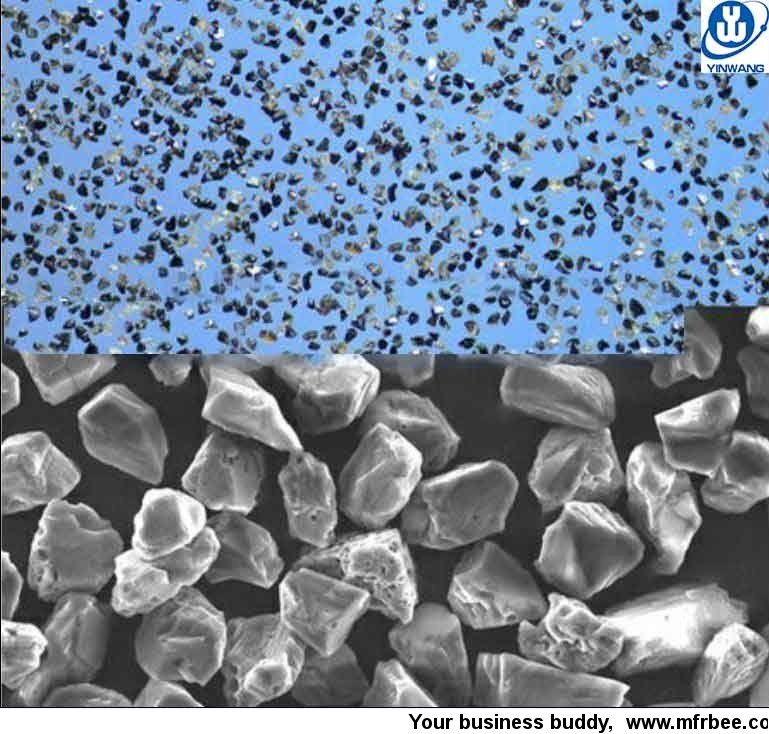

CBN micron powder

Cubic Boron Nitride (CBN) is the second hardest material only to diamond, with the high thermal conductivity, stable chemical resistance, it is suitable for working on ferrous material where

diamond abrasives are not normally employed. The CBN products are well suitable for grinding of hardened tool, alloy steel, die and nickel, cobalt-based superalloys.

CBN is the abbreviation of Cubic Boron Nitride, It is a kind of superabrasive consist of N(Nitrogen) atom and B(Boron) atom. We can get different colors like black, yellow, brown and amber CBN crystal by adjusting Nitride or Boron content during synthesizing of process. By adjusting the TI (Tough Index) or TTI (Thermal Toughness Index), the friability and strength of the CBN can be controlled to match different working requirement.

CBN single crystal size : 50/60,60/70,70/80,80/100,100/120,120/140, 140/170,170/200,200/230,230/270,270/325,325/400, 400/500,500/600

CBN micron powder : 0-0.5, 0-1, 0.5-1.5 ,0-2, 1-2, 1-3 ,3-6 ,4-8 ,5-10 ,6-12, 8-12 ,8-16, 10-20 ,15-25, 20-30, 20-40, 30-40, 40-60.

- Country: China (Mainland)

- Business Type: factory and trade company

- Market: south Asia, south America

- Founded Year: 2000

- Address: room 508. building D1, futian plaza, hanghai road

- Contact: denny fang