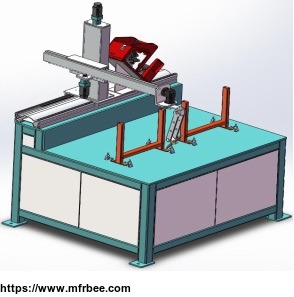

4 axis welding machine

Specifications

4 axes robot

Application

Welding workpiece: Component name: Wheeler swing arm

Product size: min 100mm -max 600mm

MIG welding

Machine can work continuously for 24-hour.

Welding Requirement

Welding seam will be flat welding or fillet welding.

Welding process does not allow the pore,crack,incomplete penetration, crater, burnt, slag, broken welding and other welding defects.

Welding seam does not leak. Little spatter and smooth welding surface.

Machine Main Characteristics

Welding torch moves, workpiece is fixed.

4axis CNC, realize right&left,forward&backward,up&down and rotation movement.

Workpiece is held and positioned by jig and fixture.

Push-type wire feeder works stably.

Welding torch can be adjustable at vertical direction.

4axis CNC system controls whole machine operation.

Machine Structure

1. Machine body is welded with square tube and thick steel.In order to avoid structural distortion, machine body is processed by Vibrating Stress Relief (VSR).

2. Right and left moving mechanism:

It is driven by AC servo motor. With the help of serve motor reducer and rack &pinion,sliding plate will move on square rails.

3. up and down moving mechanism:

It is driven by AC servo motor. With the help of serve motor reducer and ball screw,sliding plate will move on rails.

4.The project is run by numerical control system.

5. Push-type wire feeder

6. Machine is driven by AC servo motor. Servo motor reducer will guarantee smooth running during process of welding.

7. jig and fixture: installed in the working table,fix workpiece through cylinder. Jig and fixture include height adjustment mechanism. Pneumatic positioning device is used to fix workpiece

correctly, and guarantees welding reliability.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 2011

- Address: Middle Mingjia Road, Qihe Economy Development Zone, Shandong, China

- Contact: Peter zhu