Asphere Lenses

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Due to the more complex surface profile of asphere which significantly reduces or eliminate optical aberrations as compared to the simple lens, Aspheric lenses have at least one surface that is not a true sphere,It has been more widely exploited in the lens optical design stage.

Using aspheres to replace a much more complex multi-element spherical system leads to the result of the optical device can be more compact, lighter, transmit more light and in certain cases be cost effective than the multi-lens spherical design.

At Hyperion Optics, we are equipped with Optotech asphere machine which offers our customers with contour deterministic micro grinding (CDMG) service, uses the accuracy and repeatability of a computer numerically controlled machine to grind the optical shape. We start by grinding the best-fit sphere to remove the bulk material and contour the aspheric shape into the optical material from edge to center. Typical materials available of our fabrication capability are optical glass, ZnSe, ZnS, BaF2, GaAs, and chalcogenide glass. We also accept materials supplied by customers.

Optical Machining Centers capability:

- Capacities from 5mm to 400mm

- 1000 to 24,000 rpm tool spindle

- Automatic curve correction

- Tool& Workpiece probing system

- Dual tool spindles option

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2016

- Address:

- Contact:Boxin Li

Other products from Hyperion Optics

Relate products of Asphere Lenses

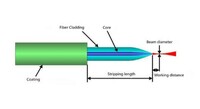

In some optical application, lens, reflector and other micro-optics components are normally needed to be assembled on optical fibers\' end face. We can also process the fiber tip into a kind of lens. At present, MEISU has the first-class optical fiber lens processing ...

GHOPTO provides various of swir imaging lenses & accessories for short wave IR camera that can satisfy your requirements in different aspects, including Fixed focal length SWIR infrared camera lens and Zoom SWIR infrared camera lens. GHOPTO Fixed focal length SWIR lens and SWIR ...