Packing Polyurethane foam Customized Packaging Foam Manufacturer

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- Packaging

- Customized

- Delivery

- 3-25 Days

Specifications

Material Specification of Conductive PE Foam

1.Basic Process

The said product is a close-cell, conductive foam. It is produced by compounding the PE resin with conductive fillers &

blowing agents to extrude certain sheets,then cross-linking and foaming. The basic process can be summarized to the following:

1.1 Pellitizing master batch by compounding PE resin with carbon black and AC foaming agents;

1.2 Extrude the said batch to make certain sheets with different thickness & width;

1.3 Cross link the said sheets under electric beam;

1.4 Make the cross linked sheets foam in foaming furnace

2..Norminal size

2.1 Normal size:

10m×1.2m×8mm; 10m×1.2m×5mm

2.2 Special size:

2.2.1 Special thickness such as 25mm, 20mm,15mm and 10mm should be ordered;

2.2.2 Small length, width and profile product are to be ordered.

Quality assurance:

1. Vinner is equiped with world advanced computer driving production lines

2. Whole set of pure water processor line featured with RO anti-saturation and advanced testing devices

3. Manufactured in Class 100,000 Cleanroom.

Contact Details:

Name:Lisa

Mobile:18871173169 (WhatsApp)

Skype:lisa520huanghua

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Africa,Americas,Europe,Oceania,Middle East

- Founded Year:2009

- Address:No. 399, Hean Road, Puzhuang Development Zone, Linhu Town, Wuzhong Area, Suzhou, Jiangsu, China (Mainland)

- Contact:lisa huang

Other products from Suzhou Sinkery Electronic Technology Co.,Ltd.

Relate products of Packing Polyurethane foam Customized Packaging Foam Manufacturer

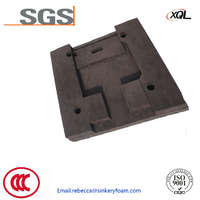

Customized Design Conductive XPE Foam Packing http://www.sinkeryfoam.com/xpe-foam-packing-p-70.html XPE(Chemical crosslinked polyethylene foam):Chemically crosslinked poly (ethylene glycol) The foamed sheet is a kind of polymer foam material which is made by mixing ...

ESD XPE Foam Packing Tray: http://www.sinkeryfoam.com/xpe-foam-c-3.html 1. Wich conduction path / network inside. excellent antistatic performance; 2. It promotes the rapid release of electrostatic without using the environmental humidity. anti-static performance is not ...

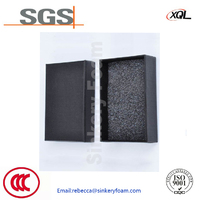

Factory Direct Sell Custom molded ESD PU Foam Packaging http://www.sinkeryfoam.com/black-polyurethane-foam-insert-with-velvet-p-127.html Product details Material Conductive PU Foam Thickness 1-100mm Color Black Surface Resistance 103-109 Ω Certificate SGS, ISO9001, ROHS MOQ No ...