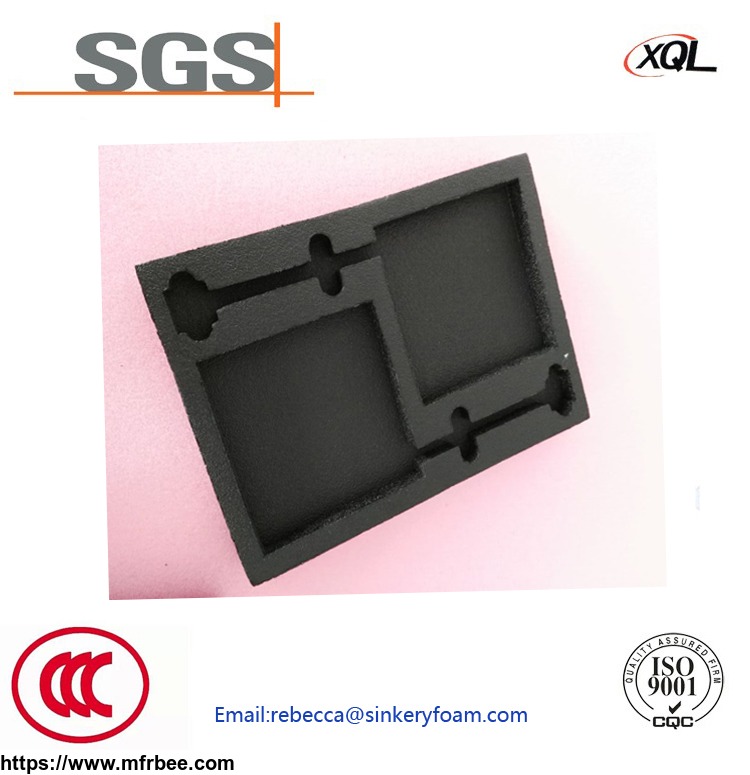

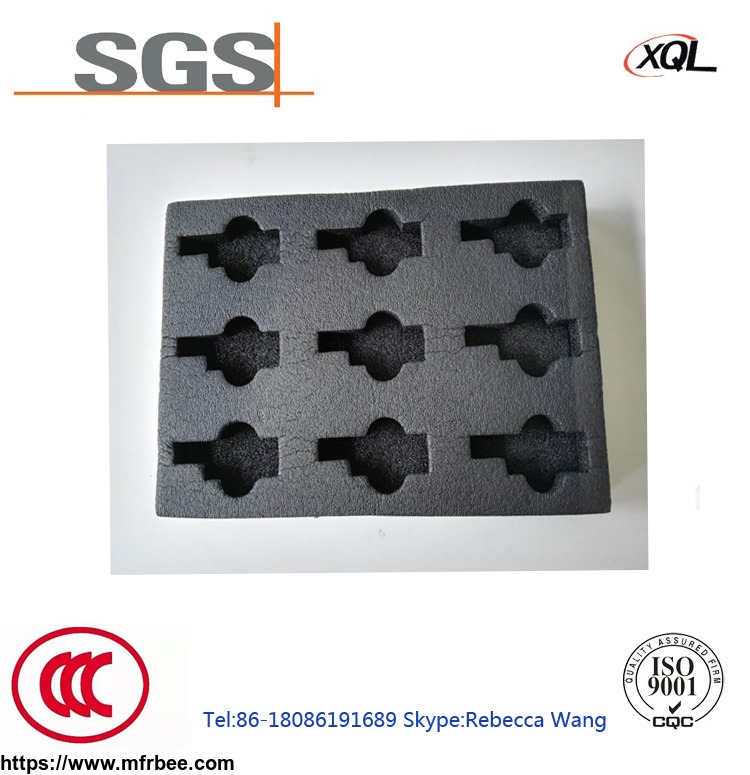

Customized ESD XPE Anti-Static Foam Packing Sheet

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China Mainland

- Price(USD)

- 0.5-2

- Material

- XPE foam

- Certificate

- SGS, ISO9001, ROHS

- Size

- Customized Accept

- Thickness

- 1-100mm

- Color

- black

- Process Type

- Pulp Moulding

- Usage

- Electronic

- Packaging

- Customized Packing with Carton

- Delivery

- 7-15 Days

Specifications

IXPE Conductive Foam

1. With conduction path / network inside. excellent anti static performance;

2. It promotes the rapid release of electrostatic without using the environmental humidity. anti-static performance is not

affected by the environmental humidity;

3. Permanent anti-static;

4. Excellent electrical conductivity, surface resistance: 103-109Ω;

5. Buffer good performance: independent and fine pore closure;

6. High temperature resistance: IXPE maximum temperature 120℃

7. Chemical resistance: resistant to organic solvents, acids, bases, etc.;

8. No chemical corrosion: It has no corrosion to the components and packaging;

9. Heat insulation, sound insulation, water absorption, moisture;

10. Good processing performance, easy molding.

Material Specification of IXPE Conductive Foam

1.BasicProcess

The said product is a close-cell, conductive foam. It is produced by compounding the PE resin with conductive fillers &

blowing agents to extrude certain sheets,then cross-linking and foaming. The basic process can be summarized to the following:

1.1 Pellitizing master batch by compounding PE resin with carbon black and AC foaming agents;

1.2 Extrude the said batch to make certain sheets with different thickness & width;

1.3 Crosslink the said sheets under electric beam;

1.4 Make the crosslinked sheets foam in foaming furnac

Applications in Optoelectronic Industry

Why choose us?

1.We are specialized in producing ESD Foam packaging since 2009, so we are more professional.

2. We can provide a reasonal price for our products because we are a factory-direct.

3. No MOQ for our products. So do not worry about if your quantity is not high enough.

4. We have advanced production, processing equipment, with strong production capacity, so the delivery date

can be guaranteed.

5.We had won the trust and support from our new and old customers with excellent service, reasonable prices.

- Country: China (Mainland)

- Market: Europe

- Founded Year: 2010

- Contact: rebecca wang