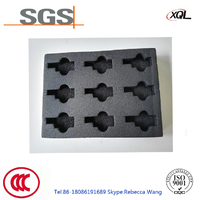

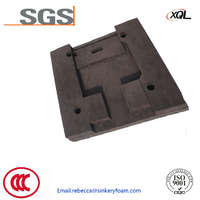

High Quality ESD XPE Conductive Foam Packaging

Product Quick Detail

- Usage

- Electronic

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Material

- XPE foam

- Certificate

- SGS, ISO9001, ROHS

- Size

- Customized Accept

- Color

- Black

- Thickness

- 1-100mm

- Process Type

- Pulp Moulding

- Brand Name

- Sinkery

- Packaging

- Customized Packing with Carton

- Delivery

- 7-15 Days

Specifications

High Quality ESD XPE Conductive Foam Packaging

IXPE Conductive Foam

Basic Process

The said product is a close-cell, conductive foam. It is produced by compounding the PE resin with conductive fillers &

blowing agents to extrude certain sheets,then cross-linking and foaming. The basic process can be summarized to the following:

1.1 Pellitizing master batch by compounding PE resin with carbon black and AC foaming agents;

1.2 Extrude the said batch to make certain sheets with different thickness & width;

1.3 Crosslink the said sheets under electric beam;

1.4 Make the crosslinked sheets foam in foaming furnac

http://www.sinkeryfoam.com/esd-ixpe-foam-c-8_10.html

Rawmaterial

| No. | Material | Content | Remark |

| 1 | PolyethyleneResin | 75—85% | RawMaterial |

| 2 | Conductive Carbon Black | 10—15% | Conductivefiller |

| 3 | AC foaming agents | 5—15% | Blowing Agent |

| 4 | Others | 3—6% | Processing Agent |

4.Technical Index

| No.. | | Data | |

| CE Series (Conductive) | DE Series (Dissipative) | ||

| 1 | Colour | Black | |

| 2 | Density | 40-60Kg/m3 | |

| 3 | Surface Resistivity | 103—106Ω/sq | 106—109Ω/sq |

| 4 | Volume Resistivity | 103—106Ω•cm | 106—109Ω•cm |

| 5 | Abrasive Potential | <50V | <100V |

| 6 | Attentuation Half-time | <1.0 . http://www.sinkeryfoam.com/esd-ixpe-foam-c-8_10.html |

- Country: China (Mainland)

- Market: Europe

- Founded Year: 2010

- Contact: rebecca wang