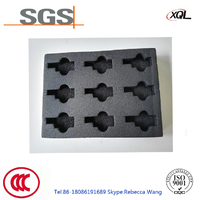

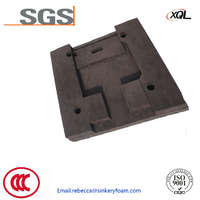

High Quality ESD XPE Conductive Foam Packaging

Product Quick Detail

- Usage

- Electronic

- Place Of Origin

- China (Mainland)

- Size

- Customized Accept

- Thickness

- 1-100mm

- Brand Name

- Sinkery

- Minimum Order

- 1

- Material

- XPE foam

- Certificate

- SGS, ISO9001, ROHS

- Color

- Black

- Process Type

- Pulp Moulding

- Packaging

- Customized Packing with Carton

- Delivery

- 7-15 Days

Specifications

High Quality ESD XPE Conductive Foam Packaging

Basic Process

The said product is a close-cell, conductive foam. It is produced by compounding the PE resin with conductive fillers &

blowing agents to extrude certain sheets,then cross-linking and foaming. The basic process can be summarized to the following:

1.1 Pellitizing master batch by compounding PE resin with carbon black and AC foaming agents;

1.2 Extrude the said batch to make certain sheets with different thickness & width;

1.3 Crosslink the said sheets under electric beam;

1.4 Make the crosslinked sheets foam in foaming furnac

http://www.sinkeryfoam.com/esd-ixpe-foam-c-8_10.html

Rawmaterial

| No. | Material | Content | Remark |

| 1 | PolyethyleneResin | 75—85% | RawMaterial |

| 2 | Conductive Carbon Black | 10—15% | Conductivefiller |

| 3 | AC foaming agents | 5—15% | Blowing Agent |

| 4 | Others | 3—6% | Processing Agent |

| No.. | | Data | |

| CE Series (Conductive) | DE Series (Dissipative) | ||

| 1 | Colour | Black | |

| 2 | Density | 40-60Kg/m3 | |

| 3 | Surface Resistivity | 103—106Ω/sq | 106—109Ω/sq |

| 4 | Volume Resistivity | 103—106Ω•cm | 106—109Ω•cm |

| 5 | Abrasive Potential | <50V | <100V |

| 6 | Attentuation Half-time | <1.0 . http://www.sinkeryfoam.com/esd-ixpe-foam-c-8_10.html |

- Country: China (Mainland)

- Business Type:

- Market:Europe

- Founded Year:2010

- Address:

- Contact:rebecca wang

Other products from JingZhou Sinkery Electronic Technology Co., Ltd

Relate products of High Quality ESD XPE Conductive Foam Packaging

Anti-static cloth is made of conductive fiber from Japan Kanebo belltron9R, there is several styles like 5MM strip, 5MM grid and 2.5MM grid. It\'s mainly used in the production of dust-proof clothing, anti-static clothing, anti-static mask, anti-static glove, anti-static shoe ...

Top Selling ESD XPE Conductive Foam Box Description: * XPE is an ideal material for heat preservation of automobiles and air conditioners. * It has developed rapidly in the sporting goods market in recent years, such as surfboard, moisture-proof mat, yoga mat and so on. * It ...