China manufacturer of EMI shielding conductive fabric

Product Quick Detail

- Place Of Origin

- China (Mainland)

- FOB Price

- USD $4.00 / Piece

- Certificate

- SGS, ISO9001, ROHS

- Thickness

- 0.08mm

- Use

- Dress, Garment

- Minimum Order

- 1

- Material

- polyester fibre + copper-nickel

- Size

- Customized * 1080m length

- Color

- Silver

- Yarn Count

- Electronic

- Packaging

- Plastic Stretched Film or Carton

- Delivery

- 5-7 Days

Specifications

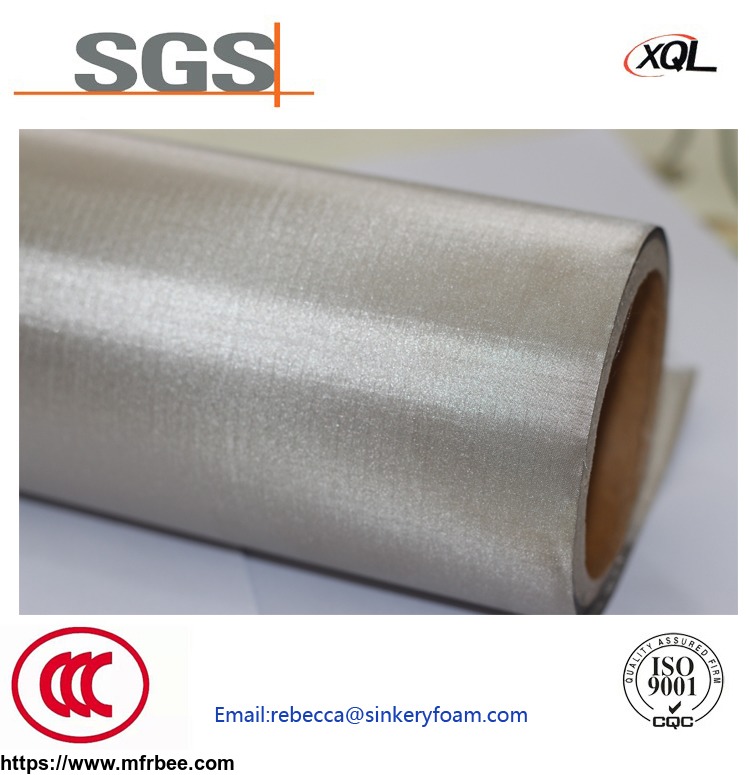

EMI shielding copper fiber conductive fabric

http://www.sinkeryfoam.com/black-coating-rfid-conductive-fabric-p-111.html

1, Metal Oxidation Resistance.

Conventional conductive cloth will be oxidized because of copper, nickel materials and air contact, hand touch, etc., the color of the cloth will change, and the shielding effectiveness of conductive fabric will decrease. Due to the protective coating, black conductive fabric, cut off the air and direct contact with the external environment, which play a role of anti oxidation of metals.

2. Electrical Conductivity.

Polymer active carbon black conductive FABRIC above has good conductivity, thus greatly enhance the shielding effectiveness of conductive fabric.

- Country: China (Mainland)

- Business Type:

- Market:Europe

- Founded Year:2010

- Address:

- Contact:rebecca wang

Other products from JingZhou Sinkery Electronic Technology Co., Ltd

Relate products of China manufacturer of EMI shielding conductive fabric

China manufacturer of EMI shielding copper conductive fabric

China manufacturer of EMI shielding copper conductive fabric http://www.sinkeryfoam.com/anti-rfid-copper-fabric-for-wallet-p-95.html Color: Silver grey Function: RFID /EMI/ EMF / RF Shielding ; Anti-Radiation ; Conductive ; Touch Screen Use For: Radiation Protection ...

China manufacturer of RFID anti-theft conductive fabric material

RFID Shielding Silver Fabric Rolls Name:RIFID Anti-Theft Fabric Material Component:polyester fibre + copper-nickel Color:Silver Thickness:0.08mm Width:1080mm Density:80g/m2 Type:Plain Fabric Technology:vacuum plating Description: Item Unit Specification Test Standard Weight ...