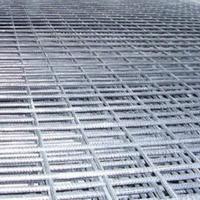

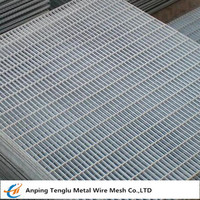

Welded Steel Bar Grating

Product Quick Detail

- Place Of Origin

- China

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 10

- Packaging

- wooden box

- Delivery

- 30 Days

Specifications

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Africa,Americas,Asia,Europe,Middle East

- Founded Year:2014

- Address:

- Contact:Emily liu

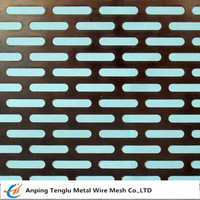

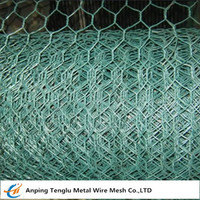

Other products from Anping Tenglu metal Wire Mesh Co.LTD

Relate products of Welded Steel Bar Grating

USE This product can be used for connecting ropes Trait Adopting high-temperature forging to enhance the hardness and load-bearing capacity of the product Material Steel Weight 110g Breaking strength 23KN Thickness 8mm Product size (mm) ...

Product Name: Nickel Alloy Bar, Nickel Alloy Rod, Stainless Steel Bar, Stainless Steel Rod Shape: Round, Square, Hex, Hollow etc. Standard: GB, AISI, ASTM, DIN, EN, JIS Process: Hot Rolled, Cold Rolled, Forged Size: Can Be Customized Inspection: TUV, BV, ABS, LR etc. Payment: ...

we carry a wide range of high-performing stainless steel and nickel alloy products. Our inventory includes a cross-section of the most popular and versatile grades on the market, and our highly experienced sales team is sure to be thoroughly familiar with the material you ...