Desanding plant

Product Quick Detail

- Place Of Origin

- China (Mainland)

- Minimum Order

- 1

- FOB Price

- USD $2.00 / Piece

- Packaging

- Standard Container

- Delivery

- 15 Days

Specifications

Brief introduction

LZ patent desanding plant is designed on the base of absorbing world advanced technology and combining with the domestic applications of the desander. it is popular for Bored Pile Slurry desanding plant, Mud recycling,TBM slurry treatment, HDD (trenchless) as well as water well drilling etc.

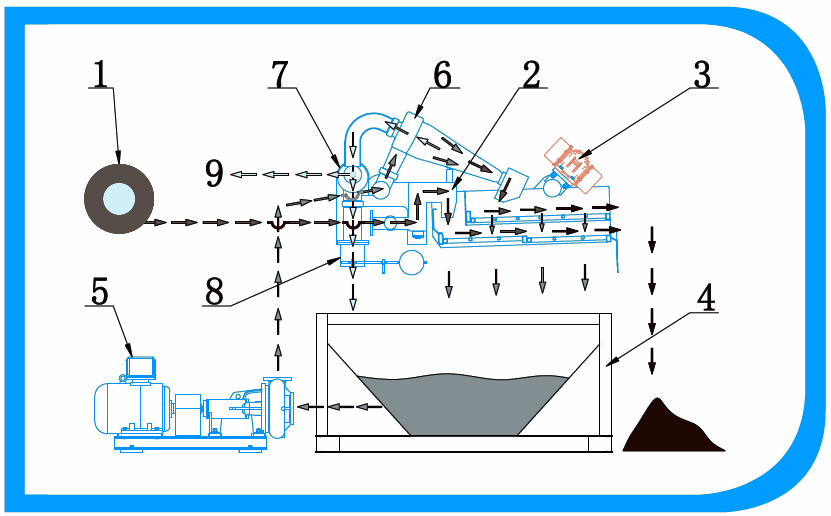

Workingprinciple

The slurry pump sucks the mud from the mud pit, then enter into bottom layer screen of shale shaker (3) through buffer box(2), the coarse particles will be separated out and the mud flow to mud storage tank (4) through the bottom layer screen of shale shaker(3). The centrifugal pump (5) takes mud from the recycling tank(4), and feed to desander cone (6) with pressure for centrifugal separation, the solids/sand was discharged to upper shaker(3) from the outlet nipple of the desander cone. After dewatering process of the upper shaker(3), the fine solids was separated out. The mud passed the upper shaker screen returns back to recycling tank(4),the clean mud entered into intermediary tank(7) through desander cone overflow pipe. The mud in the intermediary tank (7) will go out through outlet pipe (9) or go back to recycling tank (4) depends on the fluid level in the recycling tank.

In the mud circulation process, there is a fluids level float switch (8) between intermediary tank (7) and recycling tank (4), it can balance the fluids level in the recycling tank(4). When mud level is low in the recycling tank (4) the overflow from the desander will enter recycling tank (4) through the intermediary tank (7). When the mud level is too high in the recycling tank (4), the mud will overflow to the intermediary tank (7) and go out from the outlet pipe (9). If operators want to get high quality clean fluids, the feeding capacity to the system can be reduced, and the repeat cleaning process will to get the result.

Technology Advantages

1.Reduce the fine sand losing.

2.Stable vibration, long serving life and easy maintenance.

3.Fines 0.16-3mm brings good profits.

4.Unique in market, LZ patent product.

| Specification | JH-20/30 | JH-50/30 | JH-100/30 | JH-200/60 | JH-250/30 | JH-250/45 | JH-250/60 | JH-500/60 |

| Slurry feed capacity(m³/h) | 20 | 50 | 100 | 200 | 250 | 250 | 250 | 500 |

| Cut piont d50(µm) | 30 | 50 | 30 | 60 | 30 | 45 | 60-20 | 60-20 |

| Soild feed capacity(t/h) | 10 | 10-26 | 25-50 | 25-80 | 25-80 | 25-80 | 25-80 | 75-240 |

| Total capacity(kw) | 9.7 | 17.2 | 24.2 | 48 | 58-60.8 | 58-60.8 | 58-60.8 | 127-255 |

| Dismension(m) | 2.2×1.26 ×2.35 | 2.3×1.25 ×2.46 | 3.0×1.9 ×2.3 | 3.54×2.25 ×2.83 | 3.54-4.63×2.25 ×2.64-3.4 | 3.54-4.63×2.25 ×2.83-3.4 | 3.54-4.63× 2.25×2.83-3.4 | 11.7-13.3 ×5.9×5.4 |

| Weight(kg) | 1700 | 2100 | 2700 | 4800 | 4900-7600 | 4900-7600 | 4900-7600 | 21020-40000 |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,Oceania

- Founded Year: 2010

- Address: Zhongqiao Real Estate Building, Nanchang Road, Jianxi District, Luoyang, China

- Contact: gao meng