rebar tying wire

Specifications

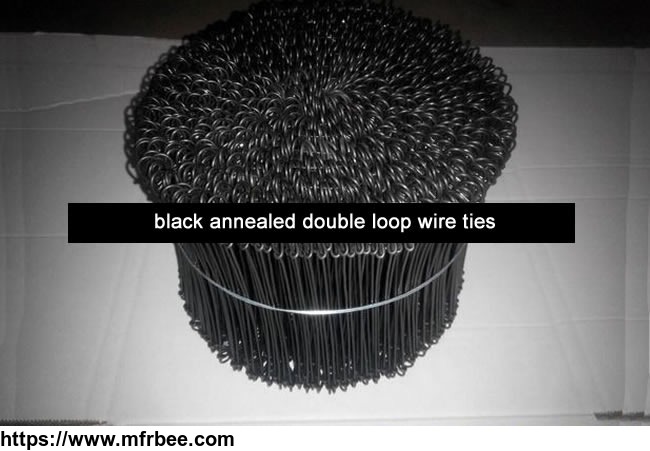

Rebar Ties for Steel Bar Secure Binding in Concrete Construction

Twisted Ties are made of plastic coated or paper wrapped mild steel wire. Used in retailing and wholesale industries for fixing openings of the the bag and bundles, packing and baling of food,

candy, bread, presents, stationeries, apparel products, and tableware. Materials can be annealed wire and galvanised iron wire for processing of twisted tie wire. Plastic coating, metallic foil

covered and paper covering optional for this metal wire tie product.

Features:

Annealed twisted ties feature good flexibility and tensile strength, soft for easy binding and fixing. Galvanized iron twisted ties feature excellent corrosion resistance, rust resistance, acid and

alkaline resistance.

Twisted tying wire is available in two forms: spools or cut lengths.

General Technical Information of Rebar Tying Wire

Wire Diameter: 22~16 Gauge

Elongation: 20-30%

Materials: Black annealed wire, galvanized steel wire, Vinyl coated iron wire, PVC coated steel, Copper coated steel, stainless steel wire.

Packing: 1000pcs/bundle, 2500pcs/bundle, 4000pcs/bundle, 5000pcs/bundle or 100pcs/bag or according to client's requirement.

Application: Tying rebar in construction and material packing.

Rolls packed by woven bag then with pallet.

Hot Dipped Galvanized Steel Construction Binding Wire

Surface Treatment: Electric Galvanized, Hot-Dipped Galvanized

Wire Diameter: 0.71mm

Gauge: BWG 22

Zinc Coated: 8-15g, High Zinc 200~300g, 10g-15g, 40g-60g

Tensile Strength: 350-550Mpa

Coil weight: 5 kg - 500 kg

Surface: smooth and silver.

Specification: 0.13mm-6.5mm.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia

- Contact: li lin