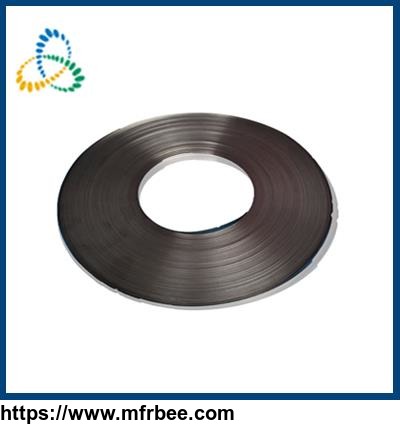

mmo coated titanium ribbon anode for cathodic protection

Product Quick Detail

- FOB Price

- USD $10.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Shaanxi

- Grade

- Gr1

- Ti Content (%)

- 99.6%

- Model Number

- mmo coated titanium ribbon anode

- Product Name

- mmo coated titanium ribbon anode

- Powder Or Not

- Not Powder

- Dimensions

- Customized

- Application

- cathodic protection

- Technique

- Coating

- Packaging

- wooden case or carton box

- Delivery

- within 7 days after payment

Specifications

The anodes are composed of titanium ribbon substrate coated with a mixed metal oxide catalyst. The anodes can achieve 50 years operating lifespan in a current density of 17mA/m. The mixed metal oxide anodes are designed for protecting the bottoms of many large-scale storage tanks. They can be used in sands with various levels of moisture and salt contents without any carbon filling materials.

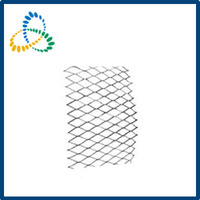

MMO meshes or ribbons were welded together by metal titanium current distribution member as impressed-current anodes in storage tanks’ bottoms for cathodic protection system.

Chemical Composition:

| Substrate | Catalyst |

| ASTM B265Gr1 or Gr2 | Mixed Metal Oxide |

Parameter:

| Width (mm) | Thickness (mm) | Length (m) | Current Output (mA/m) | Expected Life (Year) |

| 6.35 | 0.635 | 152/155 | 17 | 50 |

| 6.35 | 0.635 | 152/155 | 43 | 50 |

| 12.7 | 0.635 | 152/155 | 86 | 50 |

Titanium Substrate:

Meet ASTM Standard B265 in Grade1 or Grade2;

Advantages:

Lightweight – 100 feet of the 1/4” (6.35mm) ribbon weighs slightly more than 1lb;

Ductile – composite materials eliminate problems with breakage of brittle materials such as graphite and silicon iron;

Dimensional stability eliminates issues associated with connection seals;

Compatible with a wide range of cathodic protection media (water, coke, seawater, brackish water);

Superior corrosion resistance compared to graphite, silicon iron, and other alternative materials;

Conveniently cut and welded in the field to suit various geometries;

Durable;

Even current distribution;

Chemical corrosion resistance;

Low system electrical resistance.

Applications:

Reinforced concrete structures;

Buried steel structures;

Underground and above ground storage tanks;

Buried pipelines.

Working Environment:

Including soil, fresh water, brackish water, and seawater.

Installation Diagram:

- Country: China (Mainland)

- Business Type: Manufacturer of Titanium anode, Titanium electrodes, MMO anodes.

- Founded Year: 2006

- Address: No.32, Chuanghui Road, New Industrial Hi-Tech Zone, Xi'an, China

- Contact: Mila Meng