MMO/Ti Linear Anode for Buried pipelines

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Shaanxi

- Grade

- Gr1

- Ti Content (%)

- 99.6%

- Product Name

- MMO/Ti Linear Anode

- Model Number

- MMO/Ti Linear Anode

- Dimensions

- Customizable

- Powder Or Not

- Not Powder

- Brand Name

- Elade

- Application

- Cathodic Protection

- Packaging

- wooden case or carton box

- Delivery

- within 7 days after payment

Specifications

MMO/Ti linear anode parameter:

| Item | Parameters |

| Model P/N | ELTA-15(MMO/Ti Wire Anode 1.5mm Dia) ELTA-30(MMO/Ti Wire Anode 3mm Dia) |

| Outer Dia. | 38-40mm |

| MMO/Ti wire anode Dia. | 1.5mm,3mm |

| Current output | =52mA/m, customizable |

| Designed life | =40Y, customizable |

| Cable | 1×10mm2/ Halar,HMWPE/PVC or HMWPE are optional. |

| Carbon breeze content | =98.5% |

| Carbon breeze resistivity | ~0.05O·cm,per G.L.C.-C-12A at 23ºC, 10 bar |

| MMO wire and cable contact resistance | =0.0009O |

| Anode weight | 1.3-1.5Kg/m |

| Length per roll | 500m;1000m |

| Bursting strength | 575 N per ISO 3303 |

| Abrasion resistance | 219 cycles to failure per ASTM D-4157 |

| Fluid resistance | Pass, 6-month immersion test |

| Chlorine resistance | Pass, 6-month immersion test |

| UV resistance | 55% tear strength loss per ASTM G-53, 8 hrs @ 60ºC (140ºF), 4 hrs condensation @ 50ºC (122ºF) |

Construction:

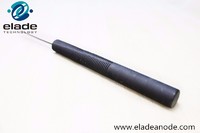

MMO/Ti Anode: Anode comprised of Titanium Wire with Iridium-based Mixed Metal Oxide (MMO) coating;

Cable: deliver the required current over considerable distance without incurring substantial longitudinal voltage drop. Halar or HMWPE are optional.

Coke breeze: Pre-packaged, high performance calcined petroleum coke breeze, serving as the active matrix in which the electrochemical reactions take place.

Fabric Housing: a continuous non-degrading fabric, allows water and vapors to pass, but contains the coke backfill.

Protective braid: Tough, porous, non-conductive protective braid enhancing the abrasion and damage resistance of the fabric jacket.

Packaging: supplied on wooden reels and suitable for export.

Through power cable and MMO/Ti wire anode, use the method of a certain distance connection seal, linear anode achieves the purpose of cable release and transmission.

Cable transmission current through MMO wire to release protection electric field, make up the composite cathode protection auxiliary anodes. This MMO/Ti linear anode has the following characteristics:

1. Low resistance between MMO wire and cable;

2. High reliability of the connection;

3. Sealing material of connection has excellent corrosion resistance and anti-aging;

4. Customizable Max current output;

5. Reliable connector connection and quality control (Helium side leakage and conductivity test for each connector).

Applications:

1.Horizontal or vertical groundbeds;

2.Above or under ground storage tanks;

3.Buried pipelines;

4.Below-Ground Storage Tanks.

Advantages :

More efficiency and economical than discrete anode;

Even distributed potential and current;

Easy design and install, for pipeline rehabilitation without excavation;

Avoids interference and shield problems;

Low resistance between MMO wire and cable;

High reliability of the connection;

Sealing material of connection has excellent corrosion resistance and anti-aging;

No impact when rebuild the cathodic protection;

No more “interference, shield”problem;

Reliable connector connection and quality control (Helium side leakage and conductivity test for each connector).

- Country: China (Mainland)

- Business Type: Manufacturer of Titanium anode, Titanium electrodes, MMO anodes.

- Founded Year: 2006

- Address: No.32, Chuanghui Road, New Industrial Hi-Tech Zone, Xi'an, China

- Contact: Mila Meng