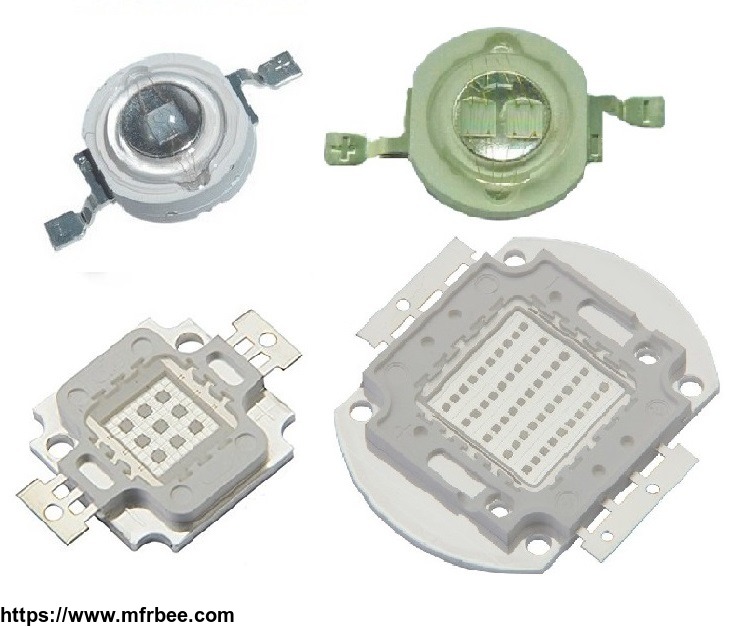

1w 3w 365-370-380-385-390-395-400-410-420-430-440-450-460-660-740-850-940nm led

Specifications

My WeChat: +8613622399214

My qq:2355433611

My email address: 2355433611@qq.com

Please contact me WeChat, QQ or email to discuss specific payment and delivery methods.

Each lamp has specific test report and spectra, please contact my WeChat, QQ or e-mail can be obtained.

My 3W 5W 10W 20W products: 1W 30W 40W 50W 60W 70W 80W 90W 100W high power LED lamp LED integrated light source LED cob integrated light

source module 3535 led

Wavelength: 365-370nm, 370-375nm, 380-385nm, 385-390nm, 390-395nm, 395-400nm, 400-405nm, 405-410nm, 410-415nm, 415-420nm, 420-425nm,

430-440nm, 450-455nm, 455-460nm, 460-465nm, 470-475nm, 490-500nm, 500-505nm, 520-530nm, 560-565nm, 590-595nm, 600-605nm, 620-630nm,

660nm, 740nm, 850nm, 940nm, white, warm white, cool white zirb, etc.

The chip brand includes:Epileds,Epistar,BRIDGELUX

Infrared voltage 1.3-1.6v

When the input current 350mA is called the 1W input current 700mA, it is called 3W, when the input current 1400mA is called 5W

The actual calculation of 1w=0.35A*1.3v=0.455w, 3w=0.7A*1.3v=0.91w, 5w=1.4A*1.3v=1.82w

Please note the difference between the call and the actual data.

UV Blue Green and white light voltage 3-3.8v

When the input current 350mA is called the 1W input current 700mA, it is called 3W, when the input current 1400mA is called 5W

The actual calculation of 1w=0.35A*3v=1.05w, 3w=0.7A*3v=2.1w, 5w=1.4A*3v=4.2w

Please note the difference between the call and the actual data.

Red orange yellow voltage 2-2.6v

When the input current 350mA is called the 1W input current 700mA, it is called 3W, when the input current 1400mA is called 5W

The actual calculation of 1w=0.35A*2v=0.7w, 3w=0.7A*2v=1.4w, 5w=1.4A*2v=2.8w

Please note the difference between the call and the actual data.

Because the power is not stable

Generally the fluctuation of current +-5% after a period of time because the device internal conversion current most easily aging big

fluctuations even more than 20% so it is easy to overload burned lamp

So the supply manufacturers generally will be the measurement of current fluctuations in advance will mark small

This will not exceed the upper limit of the light source even if the maximum fluctuation value is reached

Thus the normal use of the light source is guaranteed.

Professional LED drive power supply has a circuit to protect the light source

Aluminum substrate is only convenient for wiring and insulation, and it is recommended that the aluminum substrate be added to the LED

radiator

The bottom beads coated with thermal grease

Cling aluminum substrate

Two stitches

Like CPU\'s heat dissipation principle, the heat is transmitted through the bottom circle.

You must use LED constant current power supply, power conversion with other driving lamp cannot burn

You need to be at the bottom of aluminum substrate coated with thermal grease, screws tight to LED above the radiator, the heat will be

convenient.

Do not install in the process of LED and LED lens surface emitting regions exert any pressure, adverse action will cause the LED open

dead lights.

Please do not use the power supply constant pressure type, many customers with constant pressure type power LED lamp burned.

You need an additional radiator and drive power, which can not be powered by a switching power supply.

Konwin vertical 365-370 chip is the latest batch of light blue yellow white, please note that before buying.

The radiator will not burn lamp

The current voltage overload power will not suitable lamp burned

For special customization, please contact us and arrange the transfer.

If you receive the goods, please sign it in the face of the courier. If it doesn\'t match, please reject it immediately. We\'ll send it

back to you again. If you check it again after receipt, you will be unable to confirm it.

Although each batch of beads is the same chip production, but the production of different batches, there may be a slight difference,

please check the single test no problem and then use a lot of, don\'t just use a lot. No welding does not affect the two sale of the

beads can return, need you there can be responsible for return shipping.

The number of tiles and a single lamp led to different customers different cannot be produced in advance

LED use of attention

1. welding conditions

LED welding process is fast and the temperature can not be too high. Bad welding operation will seriously affect the performance of LED.

Please do the welding according to the following conditions:

A, manual welding: the soldering iron can\'t exceed 40W, temperature and time are 350 degrees /3S (recommend using constant temperature

soldering iron)

D, not touching LED convex welding iron process and the appearance of the LED colloid, the faulty operation will destroy the LED.

2, working conditions

A, use a constant current or current limiting circuit for driving.

B, LED working temperature can not exceed 60 degrees, higher than this temperature, please do heat treatment.

3, installation conditions

A, do not install the process of LED and LED lenses surface emitting regional imposed any pressure, adverse action will cause the death

of an open LED lamp.

Please use the LED constant current power supply and do the heat dissipation current and voltage not overload. You can\'t use other power

supply to refit the drive. Please uncover the protective film before it is lit.

Please use LED constant current supply and do not overload the current and voltage.

Please use the 10W 10w3 3 series and LED constant current power supply, power conversion with other driving lamp will burn not, such as

the PC power supply immediately burning lamp.

20W with 10 strings 2 and 30W with 10 strings 3, and so on, 100W with 10 series 10 and radiator matching the number of tiles.

Integrated lamp bottom coated with thermal grease, screws tight to the upper part of the radiator, do not install the process of LED and

LED lenses surface emitting regional imposed any pressure, adverse action will cause the death of an open LED lamp.

The fan can not blow the bare light equal to the effect of no heat dissipation, and the radiator is required.

Although each batch of beads is the same chip production, but the production of different batches, there may be a slight difference,

please check the single test no problem and then use a lot of, don\'t just use a lot. No welding does not affect the two sale of the

beads can return, need you there can be responsible for return shipping.

Attention to the application of high power LED products

During the application of high-power LED products and devices, heat dissipation, electrostatic protection and welding have a great

impact on their characteristics, which requires the attention of application customers.

1. Heat dissipation:

In the application of high power LED products, it is necessary to do a good job of heat dissipation to ensure the normal work of high

power LED products.

1. heat sink requirements.

Shape and material: if the sealing requirement of the finished product is not high, it can be directly convective with the outside air

environment. It is suggested that the aluminum or copper heat radiators with fins are used.

2. effective heat sink area:

For 1W high power white LED (the other is basically the same color) our recommended fin effective radiation total surface area is larger

than 50-60 cm. For 3W products, recommended fin effective radiation total surface area is greater than or equal to 150 cm, higher power

as the case and the test results of increase, try to ensure the temperature of the radiator is less than 60 DEG C.

3. connection method:

High power LED substrate and the heat sink is connected. Please ensure the two contact surface is smooth, good contact, in order to

strengthen the contact surface with two degree, LED suggested in the bottom of the substrate or coating a layer of heat sink thermal

grease (thermal grease thermal conductivity is larger than 3.0W/m.k), thermal grease requirements apply evenly and properly, and then

pressing and fixing screws.

Two. Electrostatic protection.

LED is a semiconductor device, which is more sensitive to static electricity, especially for white, green, blue and purple LED to

prevent static electricity and eliminate static electricity.

1. generation of static electricity:

Friction: in daily life, any two different material objects can be separated after contact, then generate static electricity, and the

most common way to generate static electricity is friction generated electricity. The better the insulation of the material is, the

easier it is to rub the electricity. In addition, any object of two different substances can be separated after contact and can produce

static electricity.

The induction for conductive materials, because the electron can flow freely on the surface of it, such as placing an electric field,

because of the repulsion and attraction, positive and negative ions will be produced on the surface of the charge transfer, will.

(3) conduction: in the case of a conductive material, a charge transfer will occur due to the free flow of electronic energy on its

surface, such as contact with a charged object.

2. the harm of static electricity to LED:

(1) the heat generated by the electric current or electric current caused the local injury of LED, which shows a rapid increase in

leakage current and still can work, but the brightness is reduced and the life is damaged.

(2) destroy the insulating layer of LED because of the electric field or current, so that the device can not work (completely

destroyed), and it is a dead lamp.

3. electrostatic protection and elimination measures:

For the entire process (production, testing, packaging, etc.) all employees with direct contact with the LED should do well to prevent

and eliminate electrostatic measures, mainly

1. Shop floor and ground floor.

2, the worktable is antistatic worktable, and the production platform is well grounded.

3. The operator wears antistatic clothing, antistatic ring, gloves or foot ring.

4, welding electric soldering iron earthing measures.

5. Antistatic materials are used in packaging.

Three. Welding.

When welding, please pay attention to the best choice of constant temperature soldering iron. The welding temperature is 260. The time

of the contact between the soldering iron and the LED plate is not 3S.

- Contact: Bin Wang