High technology factory best selling heat exchanger manufacturer

Specifications

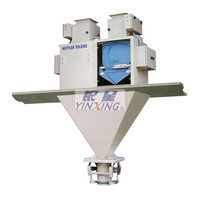

Adopts steam and air reverse circulation drying method, with low energy consumption and high thermal efficiency, small volume and can realize intelligent control.

1.Low consumption: the installation of the heat exchanger change from parallel to series, the energy consumption was reduced by 50% after reconstruction . the surplus hot air can be heat recycling

in the late of drying process , thus save more heat energy.

2.High thermal efficiency, small volume,:adopt steel fin style on the heat exchanger , improve the heat dissipation area,so that make the heat exchanger volume be light and achieve the ideal

effect.The reasonable design of pipeline and heat exchange make air drag coefficient reduced.

3.Intelligent control: reasonable arrangement good craft, make accurate drying process, curve, through the intelligent instrument and sensor system, which can realize the intelligent control of

drying process.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20,Middle East,Oceania

- Founded Year: 2005

- Contact: Ruiling Qiu