Used plastic pyrolysis plant oil to diesel oil equipment

Product Quick Detail

- FOB Price

- USD $60,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

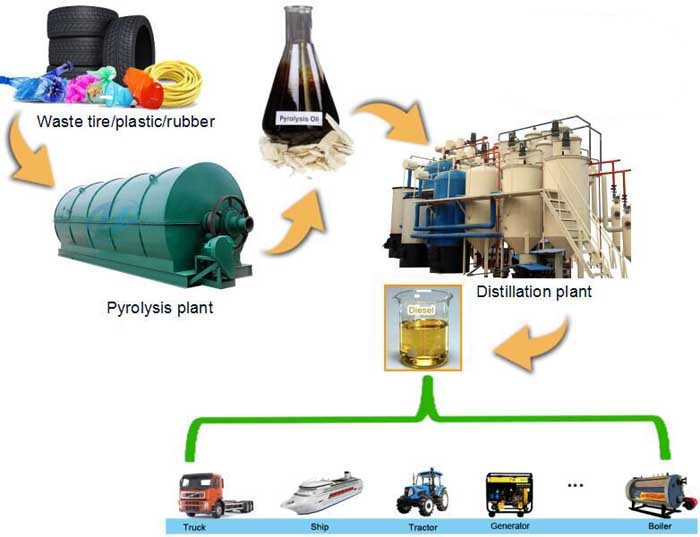

Recycling waste plastic pyrolysis plant oil to diesel oil

Waste plastics pyrolysis plant refining equipment is now very common. Common, but with the social progress, economic development, the energy crisis has become more and more serious trends. The fuel oil cracked by the refinery equipment can also alleviate the energy crisis to some extent. In order to expand the use of the oil developed by the refinery equipment, DoingGroup has developed arecycling waste plastic pyrolysis plant oil to diesel oil

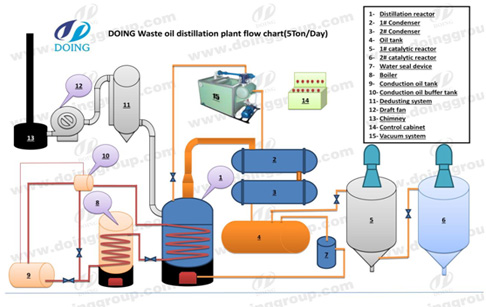

Recycling waste plastic pyrolysis plant oil to diesel oil working process

The main working flow of therecycling waste plastic pyrolysis plant oil to diesel oil

1. Pour the thermal oil into the heat transfer system and heat the base of the heat transfer system. The reactor is preheated.

2. The base of the reactor is heated and the fuel oil is distilled at a high temperature. The residue in the heavy oil can be separated and the light oil and gas will go to the next procedure.

3. Light oil and gas are liquefied through the condensing system and flow into the tank.

4. The light oil collected in the oil tank is degreased and desulfurized to obtain the final clean and transparent non-standard diesel oil.

So where does the final revenue from running ourrecycling waste plastic pyrolysis plant oil to diesel oil

Non-standard diesel usage

1. Non-standard diesel: mainly used for heavy machinery, generators, boilers.

2. Asphalt: Mainly used for paving and asphalt plant refining.

The main advantages of DoingGroup\'srecycling waste plastic pyrolysis plant oil to diesel oil

1. The vertical reactor is easier to discharge than the horizontal reactor.

2. Double heating system, both base heating, heat conduction system, heating fast, short heating time, improve equipment operating efficiency.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

http://www.doinggroup.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao