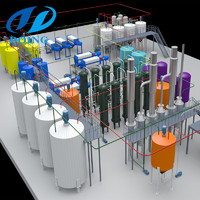

Fructose syrup production line

Product Quick Detail

- FOB Price

- USD $198,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 15pcs each cotainer

- Delivery

- 15 Days

Specifications

Fructose syrup production line

High fructose syrup is a sweetener made from starch that has been processed by glucose is omerase to convert some of its glucose into fructose in fructose syrup production line . As a sweetener, fructose syrup is often compared to sucrose, but manufacturing advantages of fructose over sucrose include that it is easier to handle and more cost-effective.

In the traditional process offructose syrup production line

The production process of highfructose rice syrup production line

1. Rice powder making processinfructose syrup production line

Produce rice powder from broken rice with dry milling method , after remove the impurity from the broken rice , the clean broken rice will be milled into powder . After milling and sieving for some times to get the quality rice powder for making the rice syrup.

2. Rice power slurry making processinfructose syrup production line

Mixing the rice powder and water to get the right density slurry. Then add the amylase and keep on the temperature for particular time to make rice powder absorbing enough water .

3. Liquefaction processinfructose syrup production line

The liquefaction process is convert the starch which contented inside of the rice powder into liquid dextrin. The material will be sprayed at high temperature by jet cooker . With the aid of amylase and steam , the starch will be converted into liquid dextrin quickly.

4. Deproteinization processinfructose syrup production line

The deproteinization process is separate the rice protein and other solid impurity from liquid dextrin by filter press. The liquid dextrin will be pumped to next process, the corn protein will be left for sale. The by product rice protein ( feed grade) is top grade protein additives for making animal feed .

5. Saccharification processinfructose syrup production line

The saccharification process is convert the liquid dextrin into required DE value glucose syrup with the aid of gluco-amylase in the tank . This process should be run under specific temperature for some hours . For making high DE glucose syrup , it will need more longer time .

6. Decolorization processfor glucose syrup infructose syrup production line

The decolorization process is removing the color of the glucose syrup by activated carbon. The glucose syrup which reached required DE will be pumped from saccharification tank into the decolorization tank , mixed with activated carbon at proper temperature .

7.Decarburization processfor glucose syrup infructose syrup production line

The decarburization process is separating the activated carbon from the glucose syrup by filter press to get clear glucose syrup.

The glucose syrup will flow into the slot and the transfer tank for next step. The activated carbon will be left.

8. Ion exchange processfor glucose syrup infructose syrup production line

The Ion exchange process is using the resin to remove the tiny foreign items and bad odor to get high quality pure glucose syrup.

The resin need regeneration by acid and alkali washing after working for some days.

9. Evaporation processfor glucose syrup infructose syrup production line

The evaporation process is evaporate the water inside the glucose syrup to increase the DS of glucose syrup to the requirement (45%) before isomerisation.

10. Isomerism processinfructose syrup production line

The isomerism process is convert the glucose syrup to fructose syrup with the aid of isomerase. The glucose is converted into with 42% content of fructose syrup.

11. Decolorization processfor fructose syrup infructose syrup production line

The decolorization process is removing the color of the fructose syrup by activated carbon. The fructose syrup will be pumped into the decolorization tank , mixed with activated carbon at proper temperature .

12. Decarburization processfor fructose syrup infructose syrup production line

The decarburization process is separating the activated carbon from the fructose syrup by filter press to get clear fructose syrup.

13. Ion exchange processfor fructose syrup infructose syrup production line

The Ion exchange process is using the resin to remove the tiny foreign items and bad odor to get high quality pure fructose syrup.

The resin need regeneration by acid and alkali washing after working for some days

14. Evaporation processfor fructose syrup infructose syrup production line

The evaporation process is evaporate the water inside the fructose syrup to increase the DS of fructose syrup to the requirement ( DS around 71%).

15. Final product storageinfructose syrup production line

The fructose syrup which reach the required DS in the evaporation process will be pumped into final product storage tanks for storage.

The final product tank can keep the fructose syrup purity before transportation.

Henan Doing Mechanical Equipment Co., Ltd, is located in Zhengzhou city, Henan province, China. Doing company is an enterprise integrating engineering, R&D, equipment manufacturing and installation, project contracting, technical services and international trading etc. We are mainly engaged in starch and syrup processing plant, cassava processing plant, contains its stand-alone device. also gluten machine.

Welcome to make an inquiry of our machine by following contacts:

Contact: Ms Elina

Email: sales@doingmachinery.com

Tel: 0086 371 5677 1822

Whatsapp/Phone:0086 135 2661 5783

Website:http://www.syrupmachine.com

http://www.starchprojectsolution.com

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Africa,Asia

- Founded Year: 1999

- Address: Yaozhai Road, Jinshui District

- Contact: konis zhang