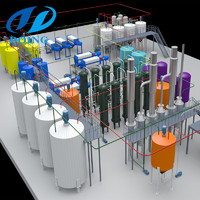

Maltose syrup processing plant

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- Packaging

- 15pcs each cotainer

- Delivery

- 15 Days

Specifications

Maltose syrup processing plant

High-maltose corn syrup

(1) Corn to make corn flour firstly.

(2) Corn flour milk adjustment: adding a certain amount of water in the corn flour to achieve the above conditions then go to the next section.

(3) Liquefaction: corn flour milk is sent to buffer tank then liquefied by jet cooker with the aid of enzyme.

(4) Deproteinization: use the filter press to separate the corn protein

(5) Saccharification: The liquefied material keeps reaction for a certain time under the action of enzyme.The required DE value of the glucose will be produced.Then the material is sent to the enzyme killer to kill the enzyme.

(6) Filtration and decolorization: Glucose gets through the filter to remove protein and other impurities,then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and send to the next section.

(7) Evaporation: The glucose is totally cleaned through safety filter machine then sent to evaporator for concentrating to reach the required DS as final product.

Henan Doing Mechanical Equipment Co., Ltd

Welcome to make an inquiry of our machine by following contacts:

Contact: Ms Elina

Email: sales@doingmachinery.com

Tel: 0086 371 5677 1822

Whatsapp/Phone:0086 135 2661 5783

Website:http://www.syrupmachine.com

http://www.starchprojectsolution.com- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Africa,Asia

- Founded Year: 1999

- Address: Yaozhai Road, Jinshui District

- Contact: konis zhang