Recycling tyre to oil process by pyrolysis plant

Product Quick Detail

- FOB Price

- USD $50,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

Recycling tyre to oil process by pyrolysis plant

With the development of economy, the number of autos has become more and more, and the number of tires that are replaced from automobiles is also amazing. These waste tires have caused a new type of pollution called "black pollution" to the environment. Moreover, the characteristics of used tires determine that if the tires are scrapped, they cannot be maintained, otherwise they will cause traffic accidents. How to deal with these used tire defects does not cause secondary pollution and damage to the environment. This is something that the entire community should consider.Recycling tyre to oil process by pyrolysis plant

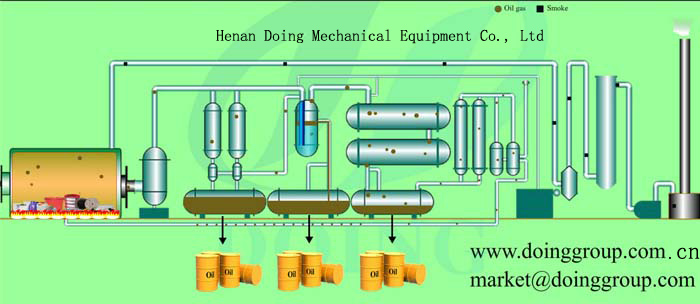

Recycling tyre to oil process by pyrolysis plant working process

What is the main job of therecycling tyre to oil process by pyrolysis plant

1. The waste tires are fed into the reactor via an automatic pushing device.

2. Heat the reactor with fuel. When the temperature rises to a certain extent, waste tires begin to crack into oil and gas.

3. These hydrocarbons enter the condensing system and are liquefied into fuel oil. The other part that is liquefied will be filtered again by the condensing system until the oil and gas are fully recycled.

4. When the temperature of the reactor drops below 40 degrees, remove the carbon black and steel wires.

The profit from the operation of DoingGroup'srecycling tyre to oil process by pyrolysis plant

Fuel oil usage

1. Fuel oil: Mainly used in iron and steel plants, boiler heating, heavy oil generators, and cement plants.

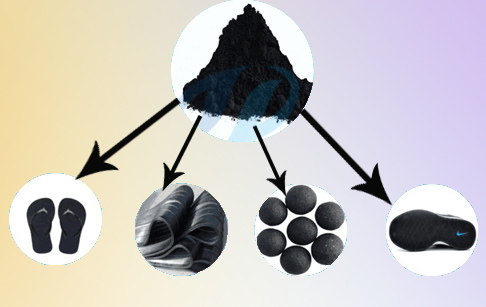

Carbon black usage

2. Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tires, rubber soles, and pigments.

The main advantages of DoingGroup'srecycling tyre to oil process by pyrolysis plant

Safety:

1. Automatic welding, improve work efficiency, ensure machine quality, avoid accidents.

2. Special design to avoid paper jam caused by X-ray inspection and ensure safe operation.

3. The vacuum system ensures that the entire production line runs well.

Environmental protection:

1. Dust removal and sulfur removal system to remove smoke and sulfur.

2. Exhaust gas (including methane to butane) will be directly recycled to the fuel furnace without gas pollution.

High oil yield:

1. Three cooling processes to ensure full liquefaction of oil and gas.

2. The catalyst chamber ensures complete pyrolysis of the feedstock.

long lasting:

1. Special boiler plate: 16mm thick Q245R.

2. Automatic welding ensures the service life of the machine and its service life will reach 8-10 years.

Energy saving:

1. The heating system is well-sealed, airtight, and fuel-efficient.

2. Exhaust gas will be recycled for reactor heating.

Good after-sales service:

1. Overseas tour guides install and train customer staff and try to run.

2. One year warranty.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

http://www.doinggroup.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao