Rock Wool Panel

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- FOB Price

- USD $3.00 / Piece

- Packaging

- plastic bag inside and carton outside.

- Delivery

- 15 Days

Specifications

High Quality Thermal Insulation Aluminum Foil Laminated Waterproof Anti-Moisture Rock Wool

| Product Description of Aluminum Foil Laminated Rock Wool |

Aluminum foil laminated rock wool is high strength board, used high-quality basalt ore as main raw material, through the high temperature melting and high speed centrifugal wire into fiber, with three dimensional method advanced production technology, added a few binding agent, shaped by thermal curing.

| Data of Aluminum Foil Laminated Rock Wool |

| Performance | Indicators |

| Thermal conductivity | 0.030--0.044w/mk |

| Slag nodule content | ≤ 12.0 % |

| Non-combustibility | A1 (nonflaming) |

| Fiber diameter | ≤7.0 μm |

| Applicable Temperature | 268-600 |

| Moisture | ≤0.5% |

| Hydrophobic rate ( Moisture-proof mineral wool board ) | ≥ 98 % |

| Character of Aluminum Foil Laminated Rock Wool |

1. Excellent fiber strength, low shot content and excellent heat presentation.

2. High hydrophobic fate, low moisture absorption rate.

3. High porosity enables the fibre rock wool products has good sound absorption.

4. Fireproof and excellent thermal insulation.

| Application of Aluminum Foil Laminated Rock Wool |

| APPLICATION | CASE |

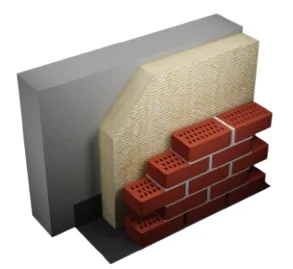

| Rock wool board External Wall insulation solution It is used for energy saving of insulation for new building and building reform It uses for frame structure, masonry structure etc |  |

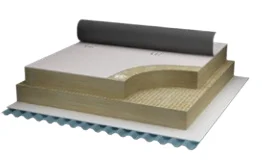

| Metal base flexible waterproof roofing solution Features: High compressive strength and resistance to point load, convenient maintenance High fire level, effectively prevent the spread of fire through a large area of the roof The waterproof layer and fire-blocking rock wool layer without isolation layer |  |

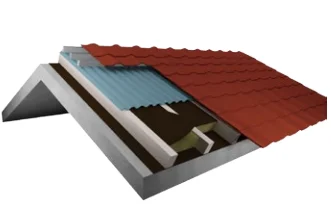

| Slope tile roof system The tile roof usually has certain slope, the design and construction of fibre rock wool is different with flat roof. The slope roof is normally for low building and multistory residence buildings. |  |

| Dry type internal partition wall It is widely used various indoor partition wall like office, mall, cinema, hotel, entertainment center, reading area, bedroom, it can create cozy and quiet indoor environment, also is suitable for building rebuild /extended or function change. |  |

| Sandwich board partition Sandwich board is used for reinforcing the internal wall horizontal install on vertical keel. If it is installed single span, only reinforcing top and bottom, no need finishing treatment. |  |

| Heat preservation for roof, ceiling, sandwich wall, attic fireproof roofing rock wool for building, Please inquiry as request. |  |

| Sandwich panel external wall solution The sandwich panel external wall system is widely used in various commercial buildings, public buildings and industrial buildings. |  |

| Shipping and Packing of Aluminum Foil Laminated Rock Wool |

1. Payment:T/T 30% advanced payment,before delivery all the goods,customers should pay for the rest of account.

2. The delivery port: Tianjin Port,Shanghai Porto or any China port.

3. The delivery time: about 7-10days

4. Rock wool board is packed by polyethylene plastic shrink film and each package thickness of 300 to 400 mm.

5. In the transport and storage process should pay attention to moisture and compressible deformation.

6. On fumigation wooden pallets with plastic films.

| Certification of Aluminum Foil Laminated Rock Wool |

Our products have passed the ISO9000 certification, CE certification, all products are in accordance with ISO9000:2000 quality management.Our diversity of products, to meet all kinds of consumer demand.

| Company |

TianZhong thermal insulation material factory is specialized in producing rock wool insulation materials. We have our R&D centers and workshops located in Zhengzhou city, Henan province. Now we totally have 4 producing lines for Rock wool with production capacity about 10,000 tons per month.

| Customer Visiting |

Quality is us promise to you. Provide you with quality products, that is our responsibility.

| Our Service |

1. Timely response: to your inquiry in 24 hours, quickly respond mails and provide solutions.

2. Free sample: Sample and trial order are accepted for the quality evaluation.

3. Shorter delivery time: Book the earliest vessel or plane to guarantee the delivery time.

4. Professional Services: Provide high or cold temperature solutions and professionals installation and technology services for you.

| FAQ |

We are manufacturer, we have own factory.

2.Can you accept OEM or ODM?

Of course, Logo is also acceptable.

3.How much a 40' container ?

About 65 - 68 cubic meter.

4.What is your payment methods?

T/T L/C D/P Paypal West Union and others.

Yes, we have, both in Europe and Middle East. Others is planing.

- Contact: Yolanda CAI