How does a tire pyrolysis plant work?

Product Quick Detail

- FOB Price

- USD $50,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

With the development of science and technology and the progress of society, automobiles have become a must for people to travel. With the increase in cars, the number of used tires replaced is huge. Moreover, waste tires cannot be repaired again, otherwise it may cause serious traffic accidents. So how to deal with these waste tires, and to avoid re-contamination of the environment?

DoingGroup has developed awaste tire pyrolysis plant

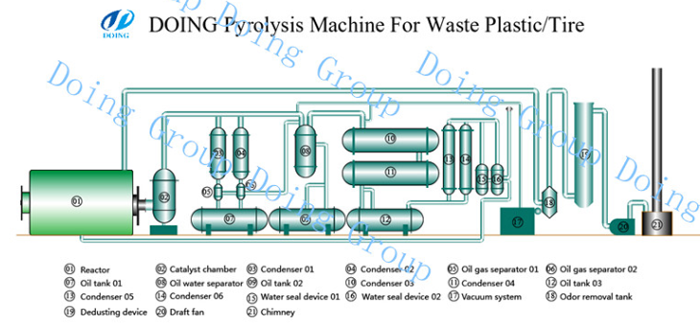

So how does thewaste tire pyrolysis plant

1. There are two options for feeding collected waste tires into the reactor:

(1) Feed the collected waste tires directly into the reactor via a pusher;

(2) The steel wire in the waste tire is first drawn out with a wire drawing machine, and then the waste tire is sent to the reaction kettle through the pusher device. This can reduce the damage of the wire to the reactor.

2. The reactor is heated with fuel or fuel. When the temperature reaches a certain height, the waste tire begins to crack into oil and gas.

3. The cracked oil and gas enters the condensing system and is liquefied into heavy oil and falls into the tank. The liquefied material will be recovered by the equipment and reused in the heating of the reactor.

4. Dust removal and deodorization of the heavy oil in the tank will result in fuel oil.

5. When the temperature of the reactor drops below 40 degrees, remove the carbon black (steel wire) from the reactor.

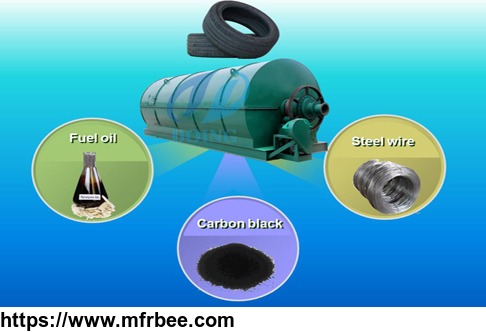

The yield of various materials used for the operation of DoingGroup'swaste tire pyrolysis plant

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

http://www.doinggroup.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao