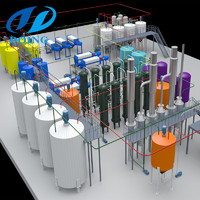

Cassava starch production line

Product Quick Detail

- FOB Price

- USD $145,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 15pcs each cotainer

- Delivery

- 15 Days

Specifications

Cassava starch production line

Cassava starch is produced by wet-milling of fresh cassava roots in cassava starch production line.A first-rate quality starch can be obtained from cassava using only water and this makes processing of cassava starch suitable for developing country.

Our company is professional manufacture the cassava starch production line . The cassava starch production line is full automatic and comprised of 12 work process as below:

1. Raw material receiving incassava starch production line

Material receiving unit is the first link ofcassava starch processing

2. Cassava cleaning and washing incassava starch production line

Clean raw materials for cassava processing play an important role, so de-stoning and cleaning unit of pre-treatment stage is the most important. The purpose of this unit is to get rid of sandstone, clay of cassava, and to deposit cleaned cassava in the cassava temporary hopper.

Cassava is conveyed into the washer, blades washer adopts counter-current cleaning principle. Water flow (used for washing) and the materials movement direction is opposite. Certain level of

cleaning water is poured into the cleaning trough, cassava raw materials almost float on the surface of water and move forward through internal trough. The cassava rotates and clashes each other in

the water, getting rid of the soil and impurities on the surface of them in the greatest degree.

After washing,the cassava fall into the crusher through the belt conveyor to carry on the preliminary slicing of cassava tuber.Cassava is cut into small piece to ensure crushing efficiency of

crushing machine.

3. Cassava crushing incassava starch production line

After washing , the cassava fall into the crusher through the belt conveyor to carry on the preliminary slicing of cassava tuber. Cassava is cut into small piece to ensure crushing efficiency of

crushing machine.

Crushing process is the most important link to influence cassava starch extraction rate. Efficient crushing machine can release cassava starch particles from cassava cells thoroughly, guaranteeing

the combination starch content of cassava residue to the minimum.Cassava slurry below the crushing machine is pumped into de-sanding unit with a fiber pump.

4. De-sanding incassava starch production line

Cassava slurry got from crushing is pumped into the de-sand cyclone through a fiber pump. Materials with certain pressure enter into the de-sand cyclone along the tangent, cassava slurry in the hydro-cyclone is rotating with high speed, light starch and cassava residue etc. overflow from the top of the hydro-cyclone, while heavy sand is discharged from the bottom of the hydro-cyclone. At the bottom there has a sand catch pot which connects pressure recoil water to guarantee starch not being discharged from underflow outlet, and the sand in the sand catch pot is discharged regularly through air valve.

5. Centrifugal extraction incassava starch production line

Centrifugal extraction unit is another key process of the whole cassava starch production line to influence cassava starch extraction rate, good centrifugal screen and process technology can help

extract out all the free starch from broken cassava cells.

Extraction unit is a centrifugal sieve group composed by three centrifugal sieves, each centrifugal sieve equips with a fiber pump and a de-foam pump. Cassava slurry came from de-sander enters into

the first level extraction sieve, under the action of centrifugal force of sieve basket high speed rotating.cassava starch goes through the screen, and the residue stayed on the surface of sieve

basket was thrown away lately.

Starch milk is pumped to hydro-cyclone for washing by de-foam pump, and cassava residue is pumped to the second stage centrifugal sieve by fiber pump. Cassava residue containing some cassava starch

is extracted starch further in the second centrifugal sieve, starchy water is pumped into the process water of the extraction unit by de-foam pump, cassava residue sequentially is pumped to the

third stage extraction sieve by fiber pump. Similarly, the third stage extraction sieve still carries on starch extraction, screened materials still enter the process water of extraction unit, and

cassava residue is pumped to cassava residue dehydration unit.

6. Cassava residue de-watering incassava starch production line

Cassava residue pumped from the extraction unit proceeds with de-watering by a centrifugal sieve, the working principle is the same as an extraction sieve. Cassava residue finally is delivered out

of the workshop through a screw conveyor, and the water of cassava residue still returns to process water system of extraction unit.

7. Concentrating and refining incassava starch production line

10.Air drying incassava starch production line

Air dryer will further dry the de-watered starch to commodities starch required moisture content. Air passes through the filter and is heated to the required temperature by the heat exchanger, and

then hot air is sucked into the flash dryer by draught fan. De-watered starch is conveyed to the feeding spiral with hopper, and then conveyed to the feeding inlet of flash dryer through spiral

conveyer; starch enters into the cyclone separator through air pipe along with hot air of flash dryer; dried starch separates with air in cyclone separator; wet air leaves cyclone separator and

discharged through draught fan. Starch enters into finished product spiral through air locker below the cyclone separator. The big bend pipe flash dryer by special design practically proves that

the energy consumption reduces 30-40% than average.

11. Screening and storage incassava starch production line

Starch is conveyed to the starch well-distribution bunker by finished product spiral, and then the starch is conveyed to the bucket elevator through the leveraged feeder starch below the starch

well-distribution bunker, finally the starch is conveyed into the two-way conveying spiral. Starch returns to the starch well distribution bunker through two-way conveying spiral, if the moisture

content of starch can’t reach standard; starch enters into the double storehouse vibrating sieve through two-way conveying spiral, if the moisture content of starch can reach standard. The

vibrating screen sifts and clarifies dried starch, removes gelatinous and thick grain of the fine starch, makes the fineness of the finished product starch meet the standard. The starch screened

enters directly into the stainless steel starch bunker for temporary storage. The sieve mesh number of the selected double storehouse

vibrating sieve its sieve mesh is increasing from top to bottom gradually, and guarantees no blockage of the starch screening and the fineness of starch.

Adopting the starch well-distribution bunker can guarantee the balance of the finished product; starch could reach the moisture standard through the recycling of the starch well-distribution

bunker, if the dried starch is too dry or too wet. Especially when the flash dryer is under the unstable starting up condition, the moisture content of starch can be ensured to reach standard

equally through the starch well-distribution bunker.

12. Weighting and packing in cassava starch production line

The starch of storehouse will be packed into 25 kg or 50 kg per bag by automatic packing machine .

Welcome to make an inquiry of our machine by following contacts:

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Africa,Asia

- Founded Year: 1999

- Address: Yaozhai Road, Jinshui District

- Contact: konis zhang