Glucose syrup making equipment

Product Quick Detail

- FOB Price

- USD $250,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 15pcs each cotainer

- Delivery

- 15 Days

Specifications

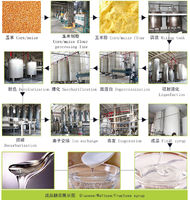

Glucose syrup making generally a industrial project, large capacity, request special equipment. Following is theproduction process of glucose syrup made

1.Mixing the starch with water to get starch milk

2.Liquefaction system

3.Saccharification

4. Saccharification liquid discoloration, and filtration process.

5.Ion exchange

6. Used multiple-effect evaporator forglucose syrup evaporation

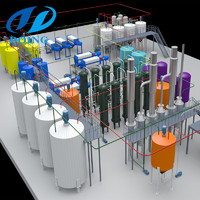

Doing factoryglucose syrup making equipment

1. Dry method directly used raw grains to make pure and bright glucose syrup.

2. No polluted water, environmental protection.

3. One set syrup equipment can product three syrup: glucose syrup, maltose syrup and fructose syrup.

4. We have different size syrup equipment, can meet all kinds of capacity requests. 3-5ton, 10-20ton, 30-50ton, 50-100ton per day, they all complete production line. Doing also can make solutions and turn-key project for you.

Welcome to make an inquiry of our machine by following contacts:

Contact: Ms Elina

Email: sales@doingmachinery.com

Tel: 0086 371 5677 1822

Whatsapp/Phone:0086 135 2661 5783

Website:http://www.syrupmachine.com

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company

- Market: Africa,Asia

- Founded Year: 1999

- Address: Yaozhai Road, Jinshui District

- Contact: konis zhang