How is pyrolysis oil obtained?

Product Quick Detail

- FOB Price

- USD $50,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

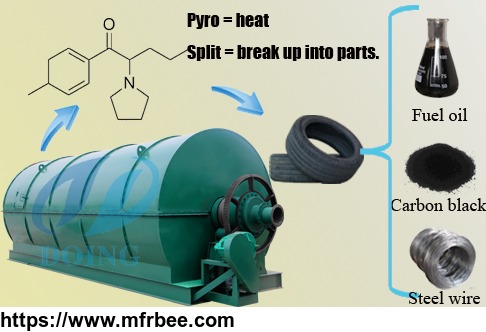

Pyro =heat, split =break up into parts. Pyrolysis is a chemical reaction in which macromolecules are broken down into smaller molecules. Waste plastics and tires are long chain molecules or polymer hydrocarbons. Pyrolysis technology is an industrial process that breaks down macromolecular plastics/tires into smaller molecules of oil, natural gas, and carbon black.

The specific steps forobtaining pyrolysis oil

1. The waste plastic/tire is fed into the reactor via an automatic push device. The reactor is heated and the waste plastic or tire undergoes pyrolysis under anaerobic conditions at about 350-550°C. The reaction time is about 15-45 minutes.

2. After the pyrolysis reaction, a large amount of oil and gas will be generated.

3. These oils and gas enter the condensing system under the action of high and low pressure, are liquefied, and fall into the tank.

4. Dust-removing and pyrolysis of the pyrolysis oil in the tank to achieve zero pollution to the environment.

Pyrolysis plant final output

Through the above pyrolysis process, we can get 45-50% of pyrolysis oil, in addition to which we can get 30% carbon black, 15% steel wire, and 10% depending on the raw material being pyrolyzed. Non-condensable gas.

There are many ways toobtain pyrolysis oil

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.continuouspyrolysisplant.com

http://www.doinggroup.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao