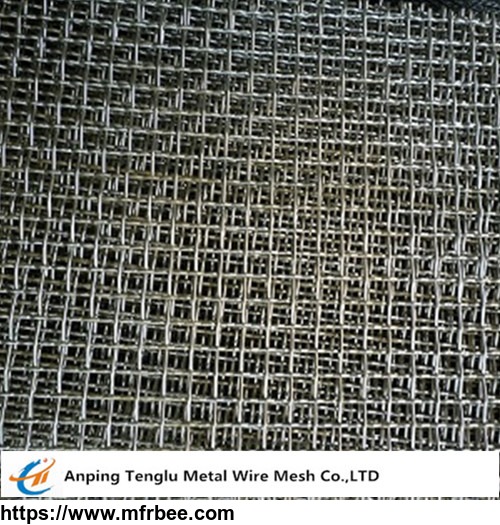

Inconel Wire Mesh

Product Quick Detail

- Place Of Origin

- China (Mainland)

- Minimum Order

- 1

- Packaging

- wooden box

- Delivery

- 15 Days

Specifications

Anping Tenglu Metal Wire Mesh Co.,LTD

Inconel Wire Mesh

•Product Description:

Inconel Mesh has excellent resistance to carburization, pitting and crevice corrosion, stress corrosion cracking and oxidation. It is resistant to a wide range of corrosive media such as organic, inorganic compounds, acids and alkali. It possesses high temperature mechanical strength, creeping resistance and long service life.

Inconel 600 Mesh: Alloy 600 has outstanding resistance to heat, oxidizing and corrosive media and offers performance temperature up to 2000oF. It is resistant to SCC and reducing media and has good mechanical characteristics from cryogenic to high temperatures.

Inconel 601 Mesh: Inconel 601 has great oxidation resistance up to 1250oC or 2200oF. It is called as a high temperature mesh material offering good spalling resistance, creeping strength and high temperature stability. It maintains ductility even after prolong service.

Inconel 617 Mesh: Alloy 617 offers elevated temperature oxidation and corrosion resistance up to 1800of. It offers high mechanical strength and great metallurgical stability. The alloy is resist to pitting and crevice corrosion and variety of strong acids such as hydrochloric acid, hydrofluoric acid, sulfuric acid and nitric acid.

Inconel 625 Mesh: It is a high strength engineered material for outstanding corrosion and oxidation resistance at the elevated temperatures up to 1093oC or 2000oF.

Inconel 718 Mesh: Alloy 718 is a precipitation hardened material for providing great high temperature corrosion resistance properties and mechanical strength. It has outstanding resistance to creeping and SCC up to 982oC.

•Materials:Inconel 600,Inconel 601,Inconel 617,Inconel 625,Inconel 718,Inconel X-750.

•Feature:

Inconel wire cloth can be used in the temperature range from low temperature to 1093 degrees Celsius.No magnetic,oxidation resistance, very good cold-formed function,good weldability, good corrosion resistance to the reducing environment of the medium intensity.

•Application:

In the chloride ion and the alkaline salt solution,no corrosion happen. Inconel wire mesh is widely used in Petrochemical, aerospace industry, hydropower, nuclear power, oil refining and shipbuilding, onshore and offshore oil and gas, pulp and paper, chemical fiber, machinery equipment manufacturing industry and the change of heat exchangers and other products, highly recognized by customers.

•Packaging :Wooden box

•Our Service:

Materials certification

Customized size

•Specifications:

| Inconel Wire Mesh | ||

| Mesh/Inch | Wire Diameter(mm) | Aperture(mm) |

| 2 | 1.6 | 11.10 |

| 4 | 0.91 | 5.44 |

| 6 | 0.71 | 3.52 |

| 8 | 0.50 | 2.67 |

| 10 | 0.50 | 2.04 |

| 12 | 0.45 | 1.66 |

| 14 | 0.40 | 1.41 |

| 16 | 0.30 | 1.28 |

| 18 | 0.25 | 1.16 |

| 20 | 0.25 | 1.02 |

| 30 | 0.21 | 0.64 |

| 40 | 0.19 | 0.45 |

| 50 | 0.15 | 0.36 |

| 60 | 0.15 | 0.27 |

| 70 | 0.13 | 0.232 |

| 80 | 0.12 | 0.197 |

| 90 | 0.11 | 0.172 |

| 100 | 0.10 | 0.154 |

| 110 | 0.09 | 0.141 |

| 120 | 0.09 | 0.122 |

| 130 | 0.07 | 0.125 |

| 140 | 0.07 | 0.111 |

| 150 | 0.06 | 0.109 |

| 160 | 0.06 | 0.098 |

| 180 | 0.053 | 0.088 |

| 200 | 0.053 | 0.074 |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Europe,Middle East

- Founded Year: 2014

- Contact: Emily liu