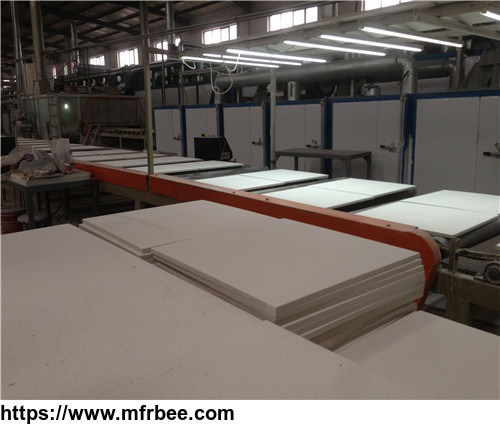

Light Mineral Wool Board Production Line Equipment

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Delivery Port

- Tianjin

- Supply Ability

- 15 Set/Sets per Year

- Set

- 270000

- Packaging

- wooden box package or null in containers

- Delivery

- 15 Days

Specifications

Light Mineral Wool Board Production Line Equipment

Product Description

Lightweight Mineral Wool Board Features

Mineral wool board mining high quality mineral wool as the main raw material, 100% free of asbestos, acicular dust will not appear, will not enter the body through the respiratory tract, harmless to the human body. The use of composite fiber and mesh base coating, greatly improving the impact resistance, deformation resistance. Mineral wool internal structure was three-dimensional cross-mesh structure, adequate internal space, solid structure, greatly improving their ability to absorb noise and noise than ordinary mineral wool board sound absorption increased by 1 to 2 times. Internal moisture and auxiliary agents to add moisture, both increasing the surface fiber resistance, effective binder stability, to maintain plate strength, and can regulate indoor humidity and improve living environment. Nano-antibacterial agent flooding the interior of the plate, can effectively mold, sterilization, antibacterial regeneration, greatly improving the scope of application, it can be applied to have the requirements of antibacterial, sterile aseptic environment. The addition of rare earth inorganic composite material enables the mineral wool board to have surface activity, strongly adsorbs and decomposes toxic substances such as formaldehyde generated during the decoration process, and has the chemical property of an ion exchanger so as to effectively increase the concentration of oxygen ions in the air. Greatly improved living space. The addition of expanded perlite with fireproof and heat insulation functions effectively reduces the cost of refrigeration and heating and meets the energy-saving and consumption-reducing needs of people in the new era.

The main raw materials and consumption table: (12 mm thick)

| Name | Quantity |

| Mineral wool | 1.35kg/㎡ |

| Perlite | 0.65kg/㎡ |

| Waste paper | 0.25kg/㎡ |

| Waterproof glue | 0.027kg/㎡ |

| Starch | 0.27kg/㎡ |

| Putty powder | 0.4kg/㎡ |

| Alumina | 0.00454 kg/㎡ |

| Glidant | 0.0078 kg/㎡ |

| Natural gas | 0.75m³ |

| Power consumption | 0.58 Degree / ㎡ |

| Water consumption | 8kg/㎡ |

1.Noise reduction: Mineral wool board to mineral wool as the main raw material, and mineral wool microporous developed to reduce acoustic reflections, echo cancellation, isolated floor noise transmission. The company is located in;

2.Sound-absorbing: Mineral wool board is a porous material, composed of numerous pores countless fibers to reduce acoustic reflection, echo cancellation, isolated floor noise transmission. Sound waves impact the surface of the material, part of which is reflected back, partially absorbed by the plate, and a portion of the material passing through the plate into the back cavity, greatly reducing the reflected sound, effectively controlling and adjusting the indoor reverberation time and reducing the noise. When used for interior decoration, the average sound absorption rate of up to 0.5 or more, suitable for offices, schools, shopping malls and other places. The company is located in;

3.Sound insulation: Through ceiling materials effectively cut off the noise of each room, creating a quiet indoor environment. The company is located in;

4.Fire resistance: To prevent fire is the most important issue of modern public buildings and high-rise building design, mineral wool board is made of non-combustible mineral wool as the main raw material in the event of a fire will not produce combustion, thus effectively preventing the spread of fire , Is the most ideal fire ceiling material. The company is located in;

5.Decorative: Mineral wool sound-absorbing board surface treatment forms rich, strong decorative plate. Surface treated knurled mineral wool board, commonly known as "caterpillars", the surface covered with shades, shapes, different pore sizes holes. Another "gypsophila", the surface of different depths of aperture. After milling forming three-dimensional mineral wool board, the surface made into small squares, different width stripes and other forms. There is also a relief-type mineral wool board, after the die-forming, beautiful surface pattern, the center flowers, cross flowers, walnut lines and other shapes, is a good decorative ceiling profiles.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas,Europe,Middle East

- Founded Year: 2005

- Address: Jinzhou Industrial Road

- Contact: Yiman Zhao