PVC faom board

Product Quick Detail

- Place Of Origin

- Shandong

- FOB Price

- USD $1.05 / Piece

- Minimum Order

- 100

- Size

- 1220*2440mm

- Packaging

- pallet

- Delivery

- 15 Days

Specifications

PVC foam board,PVC plastic board

| Product Name | PVC foam board,PVC plastic board |

| Raw Materials | PCC(PolyvinylChloride)resin,Woodpower,Impact modifier,Stabilizer,Foaming agent |

| Size | 0.915*1.525,1.22*2.44,1.56*3.05,2.05*3.05 |

| Thickness | 1-30mm |

| Density | 0.35-0.8 |

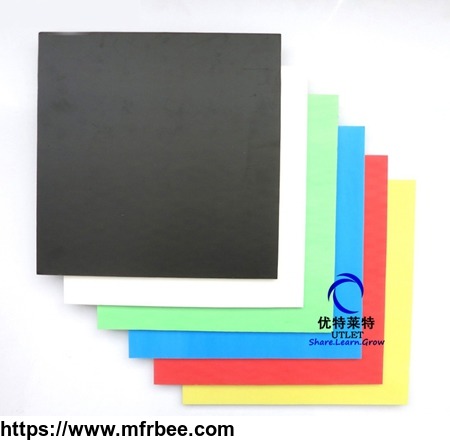

| Color | White,Black,Red,Green,Yellow,Blue,dark blue, sky blue,grass green,dark green,golden,pink,purple ect more than 20 colors for your choice |

| Type | PVC Free Foam Board,pvc celuka foam board,Co-extrusion PVC Foam Board |

| Package |

1:Several sheets are packed into PE bags

2:Pallets 3:PE bags+Pallet 4: Carton+Pallet 5:Plywood Case 6:S-K-Y-P-E: shandongutlet |

CHARACTERISTICS

1. Light weight, easy to transport, store and handle

2. Chemical and corrosion resistant

3. Weatherproof and mildew-resistant

4. Moisture resistance with low water absorption

5. Low flammability

6. Sound and thermal insulation

7. Can be drilled, sawed, nailed, bended, printed, etc.

8. Ideal substitute for wood and aluminum products

9. Various colors, sizes and thicknesses available

Characters:

1. Waterproof.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed

Application:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

4.Sanitarywares, kitchen cabinet, washroom cabinet.

PVC Sheet-applied treatments:

1.Materials processing: Cut; Drilling; Milling; nail etc.

2.Heat application: wisting, bending; Resource work; Heat styling

3.Other: Digital Printing; Application of alternative soil; Application sheets; Painting

- Country: China (Mainland)

- Business Type:

- Market:Americas,Africa,G20,Asia,Middle East

- Founded Year:2001

- Address:

- Contact:Daisy Meng

Other products from Shandong Utlet New Material Co.,Ltd

Relate products of PVC faom board

Jwell extrusion has specialized in plastic extrusion machines and complete solutions for over 25 years, also have ranked No.1 in the extrusion industry for 12 consecutive years in China, making us one of the leaders in extrusion machinery industry. This PVC, WPC panel board ...

Our company is the first manufacturer in China to develop and produce automatic PVC gypsum ceiling production line. It has fully automatic production line(single-side lamination type and double side lamination type), semi-automatic production line and economic type for ...

We have researched and developed on PVC skinning foam board extrusion machine for over 25 years, and have exported thousands of full PVC foam board production line to many countries with rich experience. Our PVC foam extrusion line adopts professional extrusion technology of ...