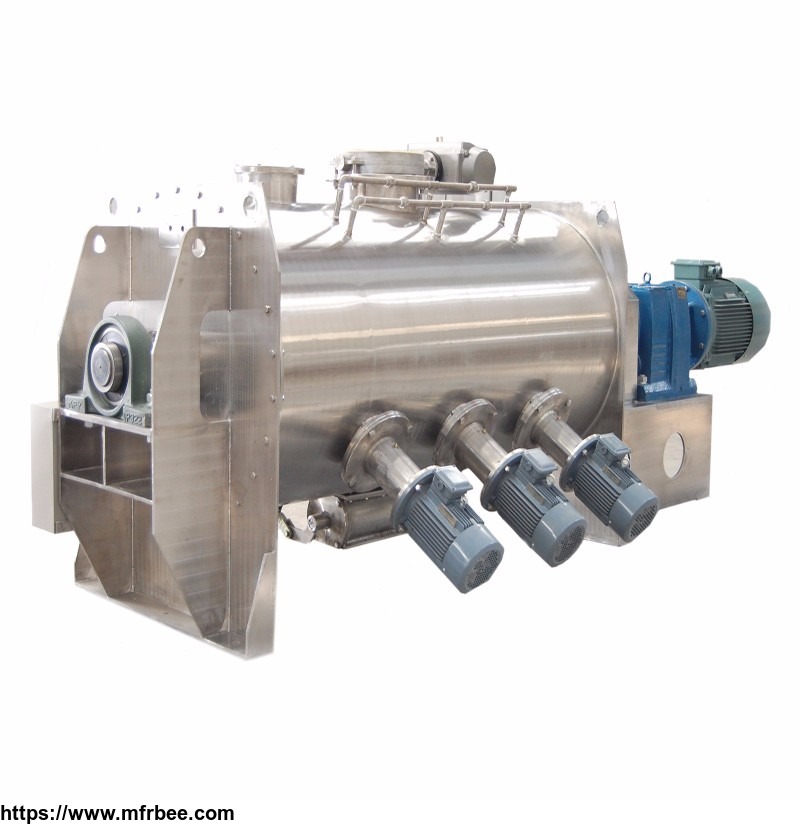

Horizontal spice powder/ingredient powder plough shear blender

Specifications

Ploughshear blender is widely used to mix powder, granule, and small liquid additives in food, chemical, and construction line.

It is particularly good at handling food additives, mortar, fertilizing, sludge, plastic, and special building material. The powerful shearing effect makes it high efficiency, and good mixing

result.

Working principles:

Ploughshear blender is a single shaft compulsory mixing equipments. Several pieces of plough shears are installed on the main shaft in dislocation and continuously, which avoid the mixing dead zone

in structure. When operating, material in mixer tank move following the direction of the continuous vortex centrifugal force generated by the continuously blending plough shears, thus to achieve

scattering, dispersing and fast mixing of material.

Special material like fiber or some damp agglomerate material, high speed chopper can be installed inside mixer tank to scatter, dispense these materials with combination of plough shear mixing

agitator.

The high speed choppers are positioned at the barrel side downward angle of 45 degrees of the ploughshear blender, the chopper heads stretch into the barrel. During mixing, materials are driven to

the effective range of the chopper, and sheared in high speed by it.

Standard Configuration:

1. Choose the batch working capacity from 0.1cbm to 20cbm, select mixer accordingly.

2. Choose raw material for the part contact with raw material, non-contact with raw material, other parts like motor and reducer, bearing material can not be chosen; According to the material to be

mixed, processing condition, health level, raw material can be mild steel, sus304, sus316L, sus321; And choose the surface treatment according to the raw material.

3. Motor power is chosen according to the material gravity, fluidity, and operation.

Operation is divided as: Start mixer when it is empty (normal duty); Start mixer with load (heavy duty)

4. Adding the auxiliary components like spraying, heating and cooling according to processing condition.

5. Mixer inlets: feeding ports, cleaning port, vent.

6. Chose discharging and driven mode: manual, pneumatic and electric.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas,Asia,Europe

- Founded Year: 1985

- Contact: Jenny Lin