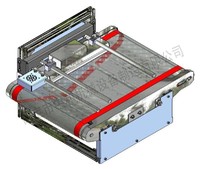

ZHRS200B-2 heat shrinkable tube heating and shrinkage machine

Product Quick Detail

- FOB Price

- USD $3,175.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- 1pcs each wooden box

- Delivery

- 15 Days

Specifications

ZHRS200B-2 heat shrinkable tube heating machine (double transmission without wire injured),especially suitable for wire harness processing enterprises to heat shrinkable tube processing needs, double-sided heating, omnidirectional reflection of hot materials to make the heat shrinkable tubes evenly heated.The heating temperature and conveying speed are stepless adjustment, which is suitable for any length of heat shrinkable tubes.

Double side heat shrinkable tube heating shrinkage machine, double side heating temperature controllable, single and double-sided heating optional, the width of the heating zone can be adjustable, omnidirectional reflection of hot materials to make the heat shrinkable tubes evenly heated.The heating temperature and conveying speed are stepless adjustment, which is suitable for any length of heat shrinkable tubes.

Apply to:

1. Connection and contraction of PE heat shrinkable tube, PVC heat shrinkable tube and double wall heat shrinkable tube with glue.

2. Thermal shrinkage of PVC pipe.

3. Thermal contraction of capacitors, batteries, wire terminals, heat shrinkable sleeves / membranes, etc.

Characteristics:

Equipment composition

Heating machine + auxiliary conveyor + control system

The temperature of double side heating can be controlled.

This machine has a digital electronic temperature controller, which controls the temperature of the heating tube and ensures uniform temperature. It can carry out 24 hours of continuous operation to ensure maximum working efficiency.

One side or double side heating is optional

According to the heating requirements of the heat shrinkable tube, it is free to choose one side or two side heating.

The width of heating zone is adjustable

The width of the heating zone can be adjusted by the user according to the size of the heat shrinkable tube, save energy as much as possible and ensure the wire do not be hurt.

Heat insulation design of heating zone

The double shell design of heating area makes the inside and outside temperature separate, that is to save energy and protect the working environment.

| classification | Item | parameter |

| Heater size | Overall machine size(L×W×H) | See picture |

| Control power(L×W×H) | 200×150×200mm | |

| Machinable maximum wire harness diameter | 20mm | |

| Maximum heating length | 120mm | |

| Heating area | See picture | |

| Cooling zone | 200mm | |

| Maximum transmission width | 200mm | |

| Maximum transmission height | 40mm | |

| Conveyor belt | Material quality | Stainless steel |

| Speed | 1~3m/min | |

| Transmission of motor power | 25W(Stepless speed regulation) | |

| Heatingpipe | Heating pipe name | Infrared tube |

| Heating pipe power | 400W,8branches | |

| Power supply for heating machine | Power demand | 220V |

| Power | 3.4KW | |

| Auxiliary conveyor | Overall machine size(L×W×H) | 1200*320*260mm |

| Maximum transmission width | 200mm | |

| Conveyer belt material | rubber | |

| The power of motor | 25W |

- Country: China (Mainland)

- Business Type: 生产厂家

- Market: 新兴市场,欧洲联盟,美洲,G20

- Founded Year: 2003

- Contact: ying shao